The Multi-Port Diverter is compact and can be installed vertically or horizontally, making it ideal for facilities with limited space. It can handle a variety of non-abrasive to moderately abrasive powders, pellets, and granules and is commonly used in agriculture, chemical, food & beverage, minerals, petrochemicals, plastics, and textile industries.

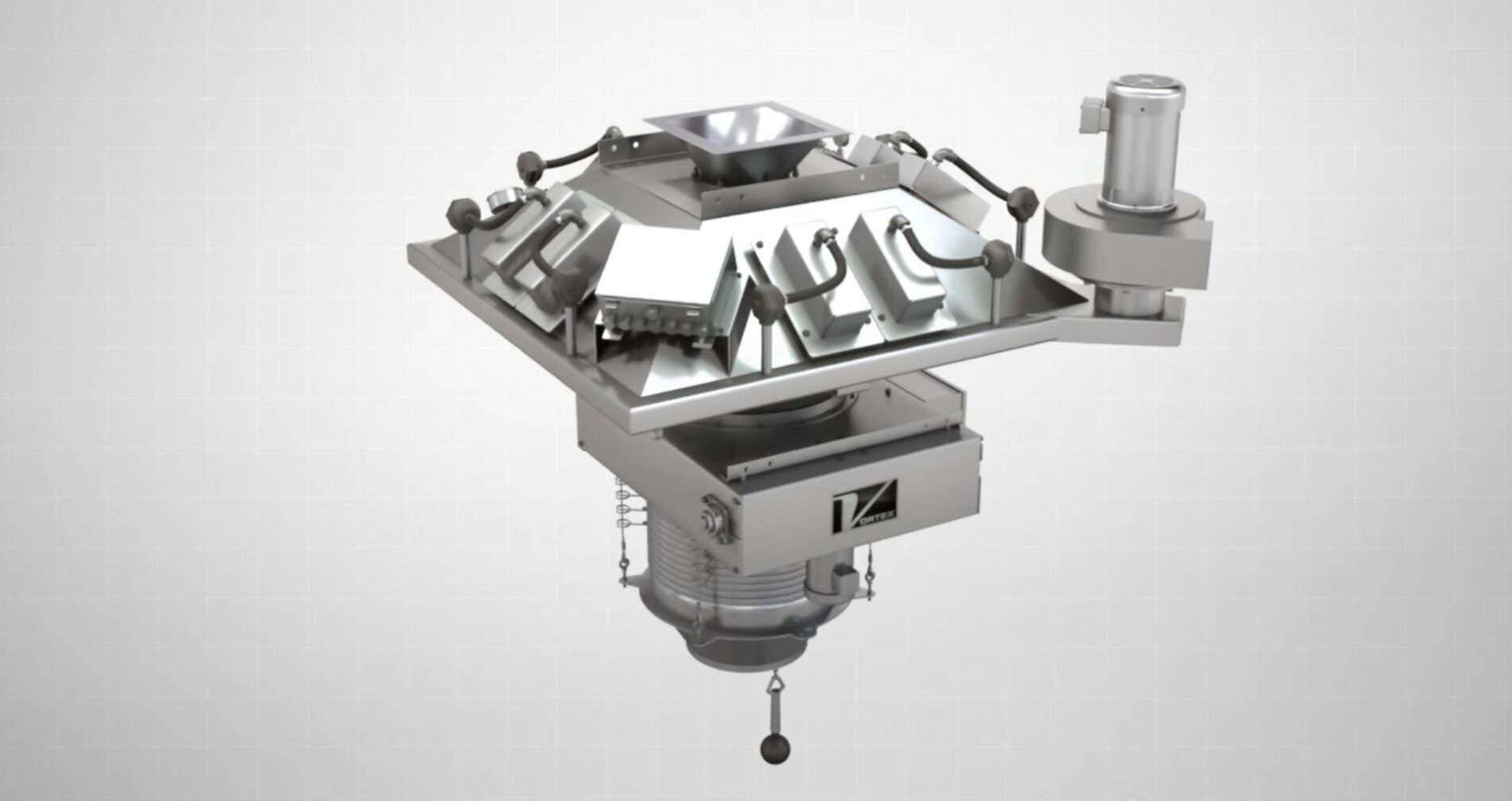

The Multi-Port Diverter is made up of several Vortex Wye Line Diverters, which have a unique design that reduces maintenance requirements. The blade of the valve is recessed and actuates into a recessed area instead of packing materials into an end seal, reducing the risk of binding and other actuation issues. It also features weep holes that indicate when maintenance is required, and shims that can be easily removed for maintenance. The Multi-Port Diverter can be shifted “on the fly” through a moving column of material, allowing for improved processing speeds.

Replacing manual hose manifold stations with an automated Multi-Port Diverter is cost-effective, reduces labor costs, and eliminates the risk of human error.

Advantages of Using Vortex Multi-Port Diverters

- Precision and accuracy: Vortex Multi-Port Diverters offer precise and accurate material flow control, which is critical for many applications. The valves can be designed to divert material to multiple destinations with precision and accuracy, ensuring that each product goes to its intended location. This is particularly important for applications that involve multiple ingredients or materials that must be kept separate to prevent contamination or other issues.

- Improved efficiency: Because Vortex Multi-Port Diverters are automated and can be shifted “on the fly,” they can improve processing speeds and overall efficiency. This means that more material can be processed in less time, resulting in higher productivity and throughput.

- Better material handling: Vortex Multi-Port Diverters are designed to handle a wide range of dry solid materials, from powders and pellets to granules and more. They can also be modified to handle higher temperatures, making them suitable for a variety of industrial applications. With their low maintenance requirements and self-cleaning design, Vortex Multi-Port Diverters can help reduce downtime and improve overall material handling performance.

Applications of Multi-Port Diverters

- Agriculture: Multi-port diverters can be used to transport and distribute agricultural products, such as grains, seeds, and fertilizers, from a single source to multiple destinations. This can be particularly useful in large-scale farming operations, where efficient and accurate distribution of materials is critical.

- Chemicals: Multi-port diverters are commonly used in the chemical industry to transport and distribute various types of powders and granules, such as catalysts, pigments, and resins. Because of their precision and accuracy, multi-port diverters can help ensure that the right amount of each material is delivered to its intended location, reducing the risk of contamination and other issues.

- Food & Beverage: Multi-port diverters can be used in the food and beverage industry to transport and distribute ingredients, such as sugar, flour, and spices, from a single source to multiple destinations. This can be particularly useful in large-scale food processing operations, where precise and efficient material handling is critical.

- Minerals: Multi-port diverters are often used in the minerals industry to transport and distribute various types of powders and granules, such as silica, alumina, and limestone. Because of their precision and accuracy, multi-port diverters can help ensure that the right amount of each material is delivered to its intended location, reducing the risk of contamination and other issues.

In summary, Vortex Multi-Port Diverters are an integrated and automated solution for diverting and/or converging dry solid materials. They offer several advantages over manual hose manifold stations, including improved safety, efficiency, and precision. With their low maintenance requirements and self-cleaning design, Vortex Multi-Port Diverters can help reduce downtime and improve overall material handling performance. They are suitable for a wide range of industrial applications, from agriculture and chemicals to food and beverage and minerals.