In addition, due to the inaccuracies they were experiencing, they frequently had to place service calls and their expectations for service were not being met. Delays in service response were causing extended down time and slowing production. The customer wanted to improve the pellet feeding control performance, weighing accuracy and service response.

The solution:

The diaper manufacturer was seeking an open system solution that would provide connectivity to their existing Rockwell Automation® PLC platform. They had talked to Hardy Process Solutions while at a local trade show and called upon Hardy to propose a solution. Based on their need for material to be continuously flowing at a precisely controlled loss-in-weight rate and a central PLC to control the flow rate setpoints, Hardy recommended its HI 4060 loss-in-weight rate controller, a three-piece load cell set, a junction box, and Hardy’s C2® cable. After supplying excitation to the load sensors and digitizing the weight signal, the HI 4060 rate controller provides an analog output to control the feeder speed and adjusts this signal based on the required rate at which the feeder is losing weight. The HI 4060 can communicate this information real-time to a PLC. The HI 4060 comes with a Secure Digital Memory Module (SMM-SD) card which automatically stores configuration data for easy transfer or data.

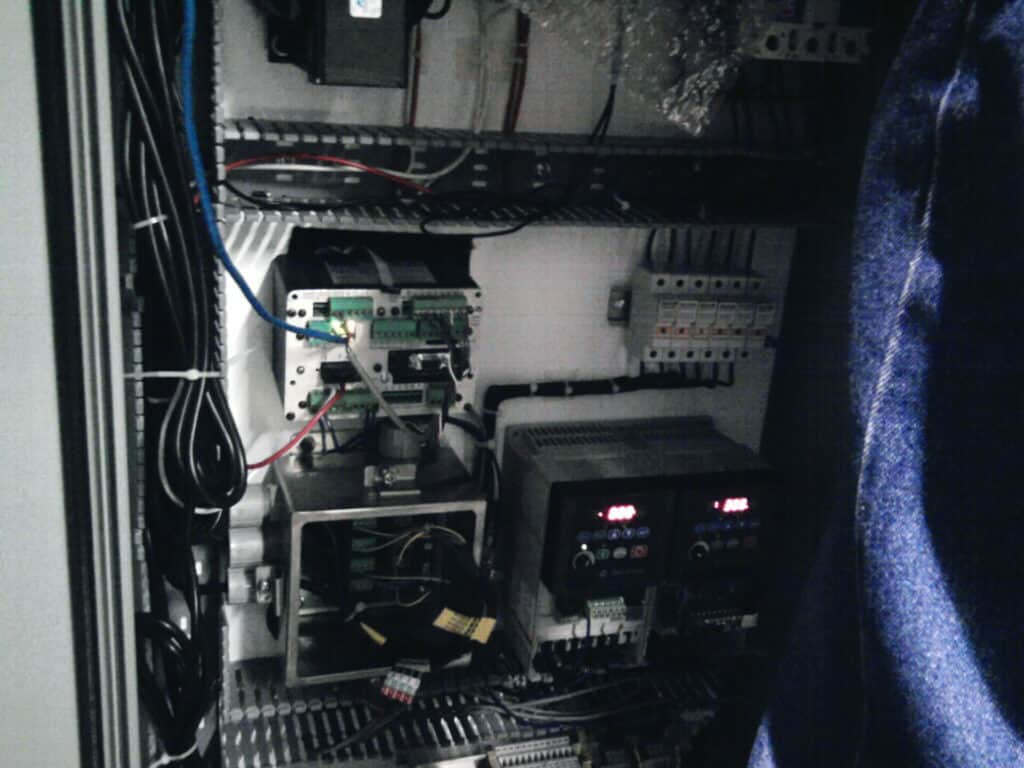

The diaper manufacturer replaced the two VFD and DC motors for AC motors and drives. They removed the closed electronics and made a panel with a Hardy HI 4060 panel mount rate controller, leaving the actual mechanics in place. The customer also replaced their existing load cells for Hardy’s ADVANTAGE® load cells for two reasons:

- The ADVANTAGE load cells are a matched strain gauge load cell that provides increased accuracy and lower unit costs.

- The ADVANTAGE load cells come with C2 Electronic Calibration which allows for accurate calibration without the need for test weights. Though not a large vessel, the layout of this production facility and access to the equipment, does not allow for easy use of test weights, making C2 Electronic Calibration ideal for this environment.

The results:

With installation of the HI 4060 loss-in-weight rate controller, this diaper manufacturer obtained both the open system and performance they desired, while experiencing a dosage accuracy of 0.5%. The user friendly rate controller, web browser functionality, connectivity and mapping provides the system operator with better access to the system along with more information about the process than they were previously receiving. This allows them to better determine if adjustments need to be made to the process.

“We are very pleased that we are now achieving the feeder control accuracy desired,” says Quality Control about the amount of super absorbent pellets required to manufacture the high-quality diaper they strive to produce. In addition, they have better quality control and less down time due to local Hardy support, allowing them to stay on target with production.

Equipment used:

Matched stainless hermetically sealed ADVANTAGE® load cells for better accuracy. HI 4060 controller, C2® cable and Hardy junction box.