Depending on the type of production, the components can be from a few to several tens. This activity is often made manually by an operator with high risk of errors and poor repeatability of the recipes.

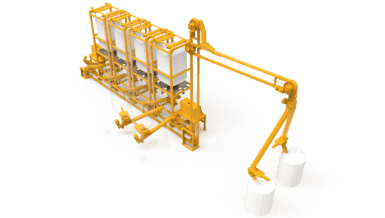

The ABC machine was designed and built to prepare automatically the recipes and manage all activities from storage to automatic bagging.

The main features are:

- High speed (1 recipe per minute)

- Precision weighing (electronic device ± 0,02% on full-scale) up to 5g on each weighing

- Big storage capacity (tanks 220l)

- Semi-Automatic loading of tanks by pneumatic convey from bags or automatic from big-bags emptying station

- Simultaneous preparation of more recipes

- Possibility of automatic bagging and marking with barcode

- Modular construction (each composed by 6 elements) according to the number of components, expandable in a second step

- Strong structure suitable for heavy use

- Delivery of machinery already tested by our workshop and full assembled

- All the preparation is controlled by PLC that lets you manage and verify:

- Components list

- Recipes List

- Weighing parameters

- Planning the production

- Manage alarms

- Consumption report

- Productivity

- Possibility of traceability in entry and exit

The machine is built in Stainless steel for the parts in contact with product and it is suitable for ATEX 22-3D zone.