Strictest quality requirements in the chemical industry

The quality requirements of the chemical industry are particularly high. As a service provider to this industry, Schirm GmbH rises to the challenge and attaches great importance to quality, transparency, reliability, resource conservation, and the protection and safety of people and the environment.

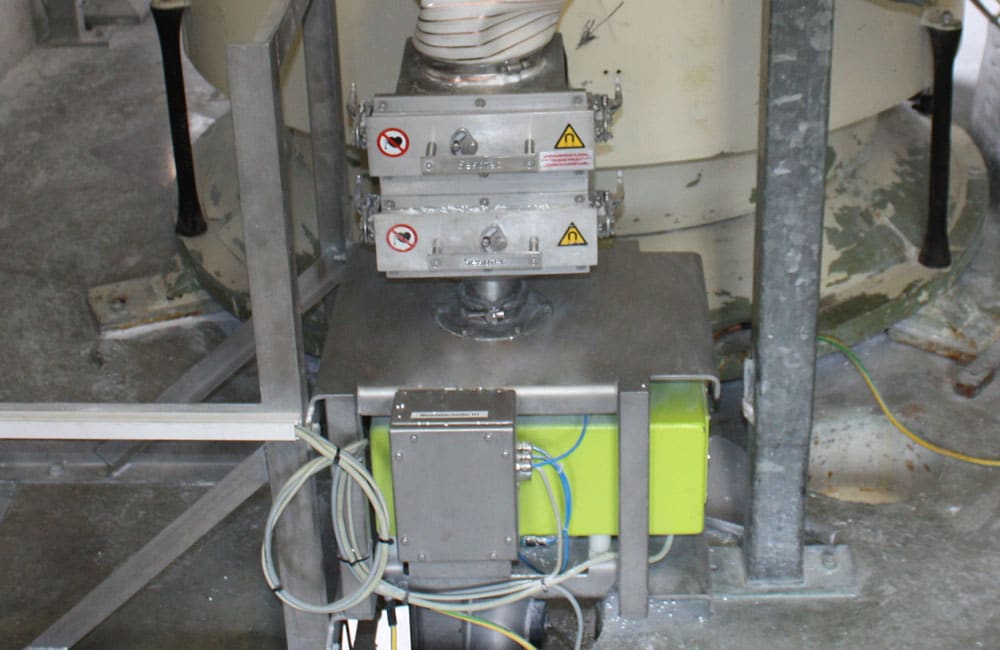

Metal detectors play an essential role in the refinement of solids to ensure consistently high product quality and safety. At the same time, the customers expect quick setup times to achieve high flexibility and efficiency. A compact design due to place limitation and the use in an ATEX 20 zone were additional requirements of the project.

Purest chemical products through multi-stage and precise metal detection

The Sesotec metal separator RAPID PRO-SENSE with control unit GENIUS+ offers extremely high sensitivity by the specially developed innovative HRF technology (High Resolution Frequency). The detection signal is sent and evaluated at a special frequency. In addition to ferrous and non-ferrous metals, RAPID PRO-SENSE detects and separates small particles of non-magnetic stainless steel. The control unit GENIUS+ with touchscreen facilitates quality control, as the data can be saved in a USB stick for further processing.

In addition, the modular device concept offers flexibility and facilitates a customized adjustment to the customer and material-specific requirements, e.g. a rotating reject outlet in case of limited space as well as a quick assembly with low effort using standard Jacob System connections.

The metal separator RAPID PRO-SENSE with a round reject mechanism without dead corners, is mainly used for outgoing quality control in the production of powder and sensitive materials with high demands on cleaning and frequent material changes. All in all, the RAPID PRO-SENSE convinces with high performance, easy cleaning, and flexible installation options.

In order to increase product quality, a combination with the inline magnetic separator MAGBOX from Sesotec was recommended. Due to the extremely high forces of the neodymium magnet material, it is possible to separate even iron dust and weakly magnetized stainless steel particles from the production stream. Magnetic separators, which are placed upstream an inductive metal separator, sort ferrous metals out and thus relieve the inductive separation.

Schirm delivers the highest quality

As a flexible and experienced production service provider, Schirm is continuously developing its range of services in line with the tasks at hand. With the uncomplicated installation of the combination metal detector and magnet, Schirm GmbH achieves the purest products with the greatest added value for the customers.

It should also be noted that the technical features of the metal separator and the magnet system as well as the close cooperation between the project partners Sesotec and Schirm GmbH were decisive for the success of this project.