This means that variations in raw materials are more likely, which means we need to either pre-condition raw materials prior to manufacturing or create a process that will allow us to create a process that allows us to ensure batch consistency regardless of raw materials variations.

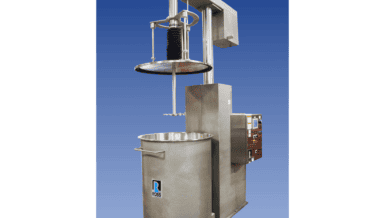

PerMix Vacuum Mixers & Dryers allow manufacturers to create a process that will allow them to ensure batch consistency regardless of variations, and will allow us to control the end result to ensure batch consistency every time. PerMix Vacuum Mixers & Dryers allow you to heat & cool while being under vacuum which allows for quicker moisture reduction of products while keeping the stability of the ingredients intact as evaporation temperatures are reduced under vacuum.

There are many other advantages also to Vacuum Mixing & Drying such as:

- Reduced evaporation temperatures

- Removal of gases during the processing stage

- Removal of oxygen reducing the possibility of oxidation

- Better batch consistency

- No pre-conditioning of raw ingredients

- Energy efficiency