As the demand for batteries continues to soar, it has become increasingly crucial to optimize the manufacturing process. By joining forces with IKA, Dec Group are well equipped to provide their customers with cutting-edge solutions that address the challenges in battery production.

With combined expertise in the industry, they are confident that this partnership will propel them to the forefront of battery manufacturing solutions and greatly enhance their ability to meet the evolving needs of the market.

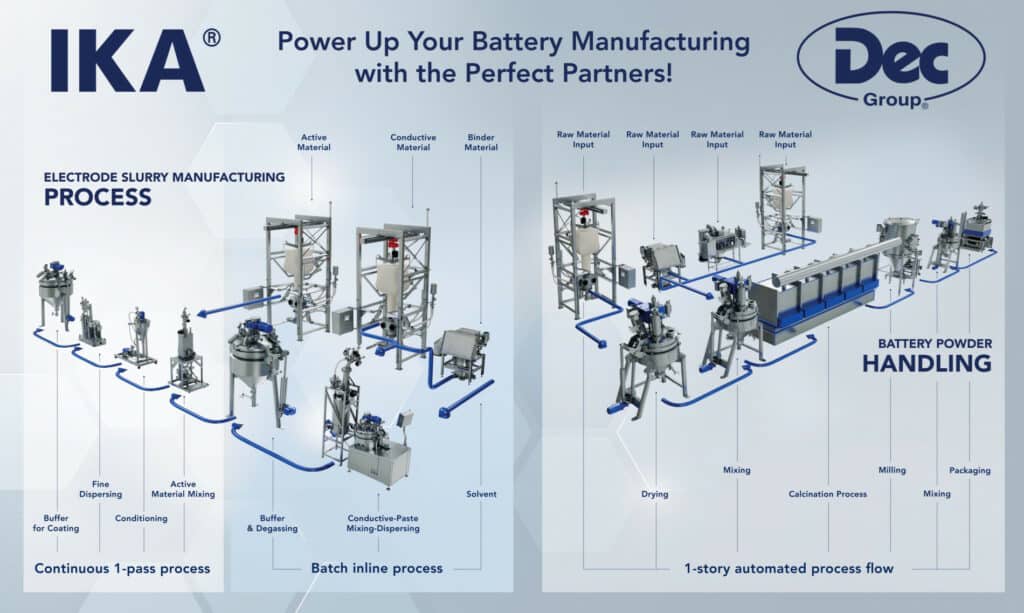

One of the key applications pertains to the battery powder handling. This critical phase requires precise control and accuracy to ensure the quality and consistency of battery components. Thanks to advanced powder handling and processing systems, Dec Group can streamline this process, minimizing waste and maximizing efficiency.

Moreover, the collaboration with IKA will also significantly bolster the electrode slurry manufacturing process. The slurry, a crucial component in battery manufacturing, requires careful attention to detail. The electrode slurry manufacturing process is an essential step in battery manufacturing, as it determines the quality of the electrodes, which significantly impact the overall performance of lithium-ion batteries. The electrode slurry is a mixture of active materials, such as NMC or LFP for the cathode or graphite for the anode, along with conductive additives, binders, and solvents.

This partnership underlines the Group’s commitment to remain at the forefront of technological advancements and provide customers with state-of-the-art solutions. By offering advanced process solutions, this partnership intends to empower customers to meet the escalating demand for batteries across various industries with high quality products and reduced production times.