REMBE® Company Profile – Consulting. Engineering. Products. Service.

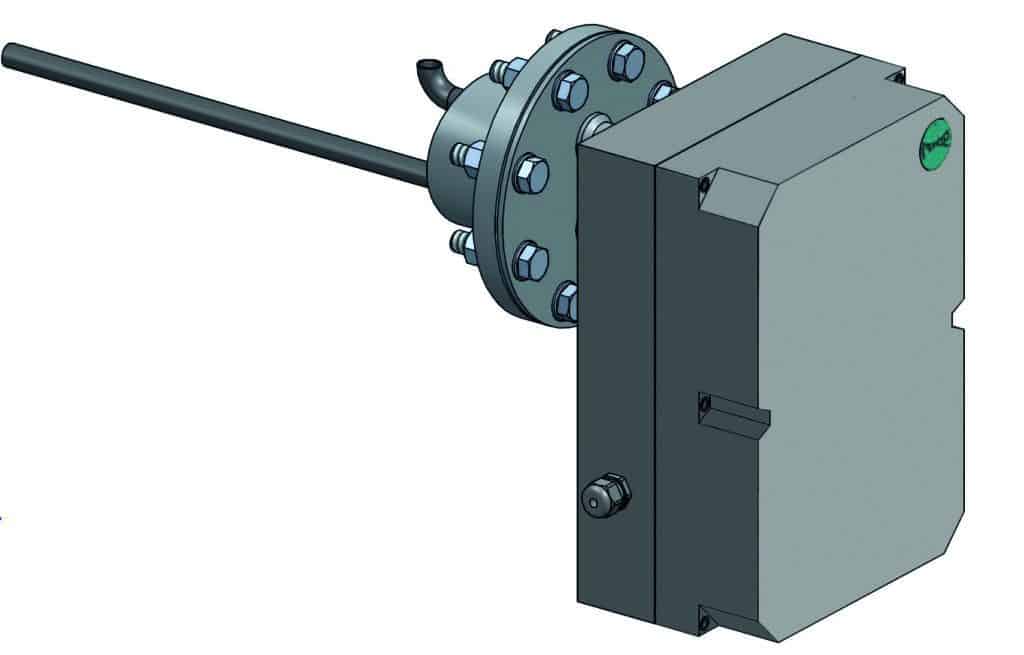

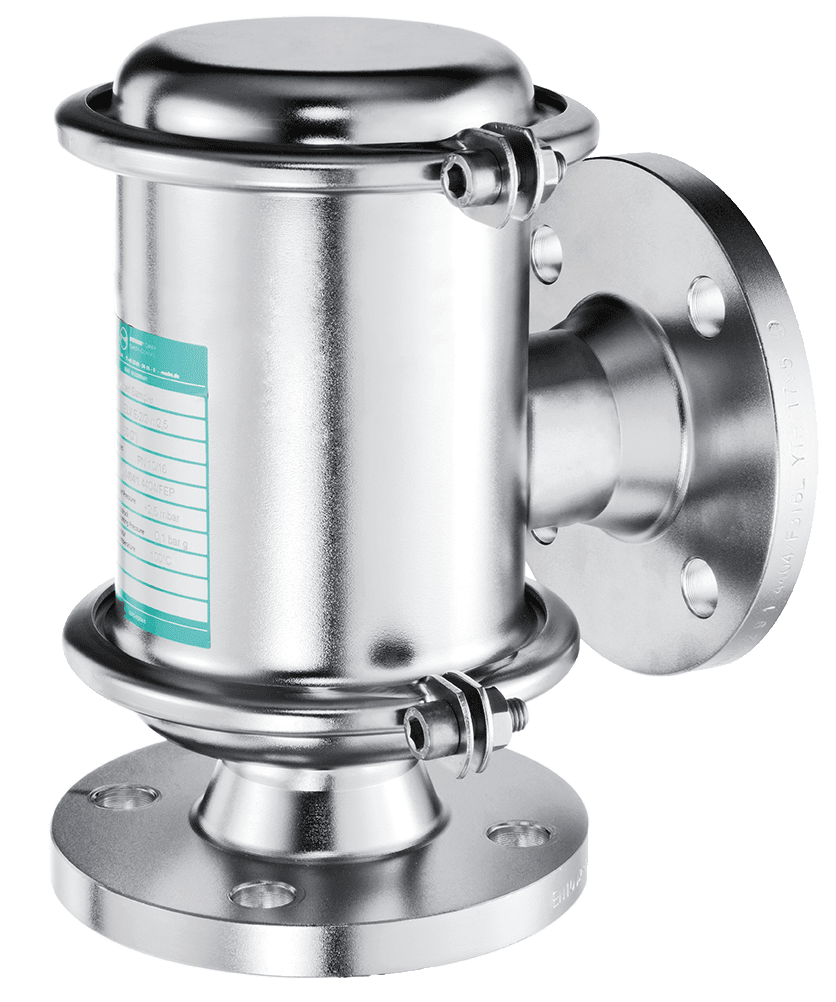

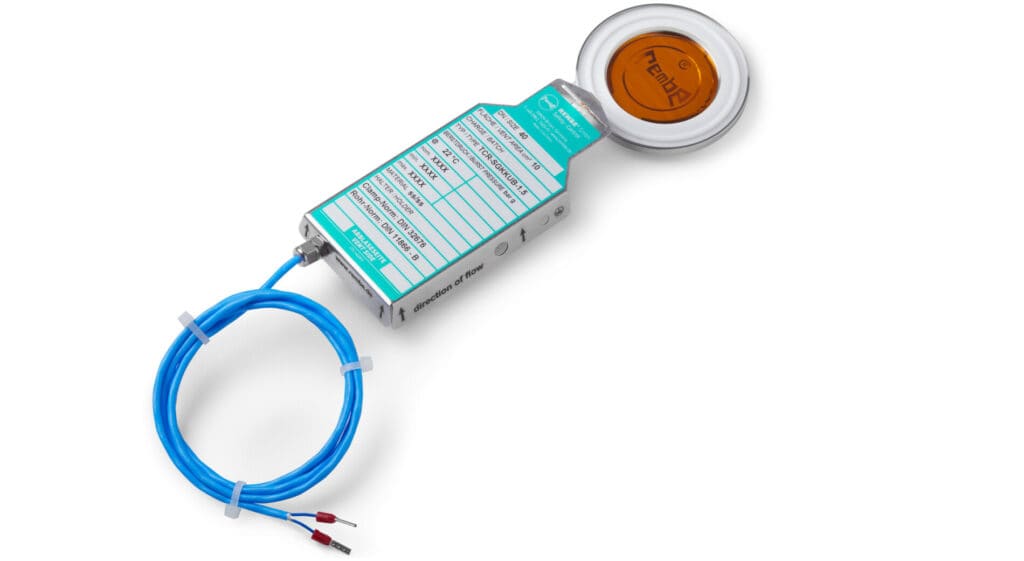

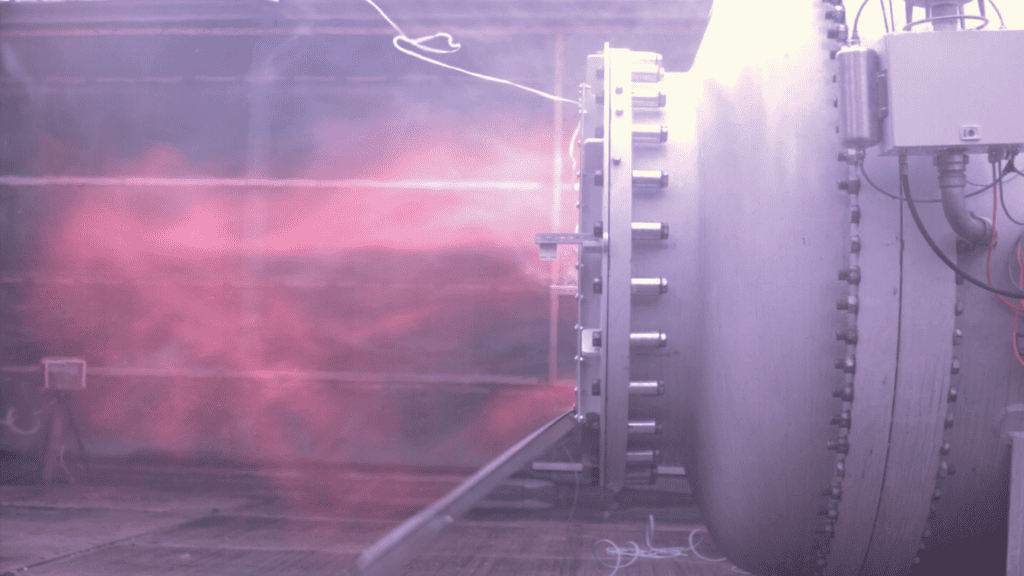

REMBE® is a safety specialist in explosion safety and pressure relief. It provides customers in all industries with safety systems for their plants and equipment. All products are made in Germany and meet the requirements of national and international regulations. REMBE® customers include market leaders in numerous sectors, such as the oil and gas, food, wood, chemical, pharmaceutical and petrochemical industries. REMBE® takes a comprehensive approach, primarily developing and making its own products while also providing the relevant consultancy, engineering and service.

The independent family enterprise, founded in 1973, employs a global workforce of around 340. REMBE® has its headquarters in Brilon, in the hills of the Sauerland region (Germany) and runs nine subsidiaries to support its worldwide customers right where they are. Thanks to its short lines of communication, the company can respond quickly and find customised solutions for all applications, ranging from standard products to special high-tech designs. Its most important proprietary products and processes include the KUB® reverse acting buckling pin rupture disc and flameless venting technology- REMBE® has active worldwide engagements on various professional bodies and is also involved in planning and setting up international standards and regulations.

Certifications

Management systems: DIN EN ISO 9001:2015, ISO/TS 29001:2010, KTA 1401, DIN EN ISO 14001:2015, DIN ISO 45001:2018

Products: RL 2014/34/EU (ATEX), IECEx, RL 2010/35/EU (TPED), TR ZU 004/2011, TR ZU 012/2011, TR ZU 020/2011, FM Global, GL, EHEDG, RL 2014/68/EU (PED), ASME Sec. VIII, Div. 1, UK SI 2016:1107, China Manufacture License, KOSHA (Südkorea), TR ZU 010/2011, TR ZU 032/2013

Testing standards: AD 2000-Merkblatt A1, EN ISO 4126-2, DIN EN 1127-1/-13463/-14373/-14491/ -14797/-14994/-15233/-16009/-16447, EN IEC 60079-0/-60079-11/-60079-31, VDI 3673, NFPA 68, NFPA 69, IEC 61508

Approval of German Aviation Authorities

Known Consignor (DE/KC/00912-01 + DE/KC/00912-02)

Approval of German Customs Authorities

AEO CS – Customs Simplifications/Security and Safety (DE AEOF 126130)