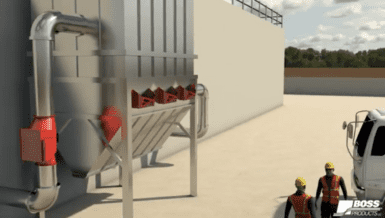

The plant had already been designed on the basis of process material characteristics with a relatively high minimum ignition energy (MIE), and easily-identifiable sources of ignition were not apparent. Consequently, there was no requirement for an explosion protection system to mitigate the serious effects of a dust explosion during operation. However, following a critical design review by an external safety consultant before the plant became fully operational, a potential explosion source was determined to be present within a product receiving vessel (day hopper). Furthermore, if an explosion had occurred within the day hopper, it was possible that flame could propagate upstream via the pneumatic conveying system, exposing interconnected equipment to explosion effects. It therefore was considered necessary to provide a reliable explosion protection system to protect the plant, process and employees prior to operation. As the design calculations for the process had not factored in the requirement for explosion protection, this presented IEP’s engineers with certain challenges and constraints.

Firstly, as the vessel strength of the hopper was insufficient to withstand the effects of an explosion, it was vital to mitigate such an explosion event before it could develop into a more serious problem with the potential to propagate to adjacent equipment and initiate a secondary explosion in the wider area. This problem would normally be solved by installing an explosion relief vent with a large enough surface area to relieve the explosion pressure in such circumstances. Since the hopper was located in the middle of a building, it was not possible to vent this to a safe area where employees and other sensitive equipment would not be present. Finally, any devices used as part of the explosion protection system would have to be “hygienic” in design and suitable for use in a food handling plant, while also complying with all necessary EU standards and regulations including ATEX, Pressure Equipment and Low Voltage directives.

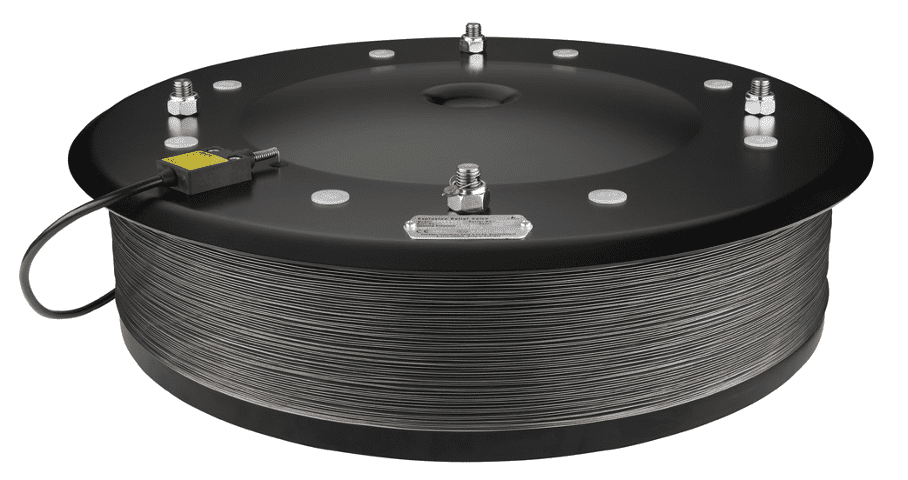

After discussions with the manufacturer and reviewing all available options, IEP’s engineers proposed a “hybrid” solution incorporating explosion isolation and flameless venting, with associated sensing and control capability. Rapid acting explosion sup- pressors were mounted on the pneumatic conveying ducting to act as an extinguishing barrier to protect connected plant against explosion propagation. To relieve the pressure created by the initial explosion an EVN30H “flameless” explosion venting device was fitted to the hopper.

The EVN30H has a special re-closing and reusable design which uses a flame arrestor to break up and cool the flame, gases and products of the explosion, meaning that it can safely be installed in an internal area where people may be working in the vicinity. The “H” classification also means that it is designed for use in hygienic applications such as the food industry, and can safely be used in contact with products intended for human consumption.

Dust explosion overview

Dust explosions can occur in many manufacturing processes when fine particulates, dispersed in air, are subjected to an ignition source within a contained environment – for example a duct, vessel, mixer, silo or dust collector. Ignition can be generated by several factors, including hot surfaces, flames, welding, spontaneous combustion, friction or uncontrolled electrostatic discharges. These ignition sources should be minimized or eliminated by a combination of effective engineering controls, safety management and operator awareness but in many cases the explosion risk is ever present and therefore techniques to mitigate the potentially catastrophic effects must be employed.

The explosion suppressors are actuated by IEP Technologies “SmartDS” dynamic pressure detec- tion system capable of rapidly detecting pressure rises created by incipient explosions, without being susceptible to spurious activation caused by varying pressure conditions inherent to the process. All elements of the system status were monitored and logged by IEP’s EX100 controller.

The overall project was executed by IEP’s European Hub, based in Ratingen (Düsseldorf), Germany working alongside a respected German Food Processing Equipment Manufacturer and involved engineers and technicians from all disciplines including sales, design and service. IEP engineers provided operator training during pre-start up commissioning and will also visit the plant for planned annual maintenance.

In view of the hybrid explosion protection system selected, employing both active and passive devices, the sugar processing plant was able to gain final insurance acceptance and go safely into operation on schedule.

The constraints and challenges that needed to be overcome to complete this project perfectly illustrate IEP’s capability as a Trusted Industrial Explosion Protection Partner, comprising material testing, engineering review and design, system supply and ongoing maintenance, training and support. IEP Technologies is part of the global HOERBIGER Safety Solutions network, with local sales, service and support centers throughout Europe as well as North America, Latin America, Middle East/Africa and Asia/Pacific.