With the growth in protein bar retail value expected to double in the coming years to 14% CAGR (2019-2023)¹, the customer needed a pilot-size mixer that could conduct trials during their development phase to replicate large scale industrial production methods. The customer’s bakery mixers, used for similar pilots, were not able to mix the dense ingredients of whey protein isolate and dairy proteins sufficiently to be effective. The company required a high torque kneading and folding mixer that could effectively mix 5kg batches.

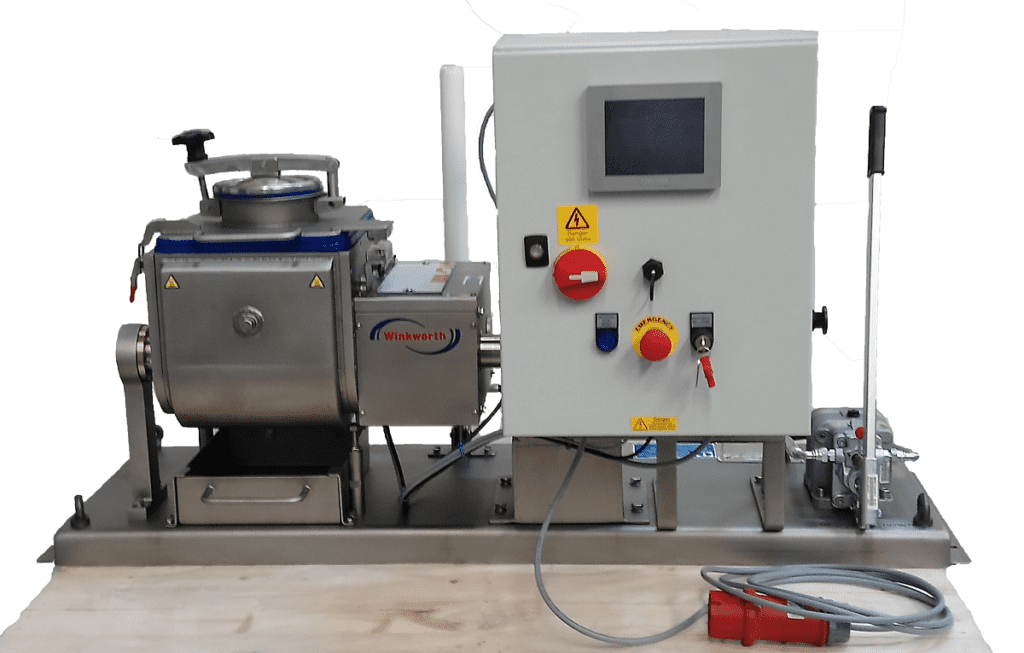

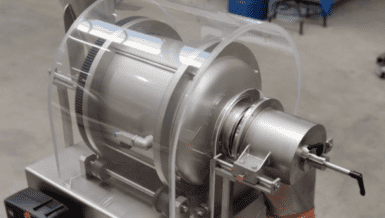

Winkworth recommended their stainless steel MZ10 high shear mixer, which is ideal for mixing, kneading and blending of dense materials for development. Featuring twin heavy duty Z blades and a manually operated hydraulic tilting mechanism, the 10 litre capacity of Winkworth’s range of laboratory and pilot mixers are small enough to reduce waste, yet large enough to be representative of production reality. This accurate representation of production performance typically provides a scalable outcome prior to full capital investment.

“Throughout this smooth process we had good support from Winkworth – the mixer is ideal for our requirements and is delivering what we hoped for,” commented Winkworth’s customer. “We are frequently showing the mixer to our customers who, like us, are very impressed with its capabilities.”

“The MZ10 is ideal in this case,” added Winkworth’s technical director, Tim Simpson. “Being able to mix small batches means that it is perfect for pilot studies and trials, and with its high torque capability it’s more than capable of mixing dense material. Of course, once the pilot has successfully concluded, we can provide customers production scale mixers up to 1500 litres batch volumes as required, and larger on request. For the protein/energy bar market specifically, several companies have adopted our larger scale Winkworth Z Blade production mixers, which have proved ideal. ”

Winkworth has been designing and manufacturing world-class industrial mixers, paddle mixers and blenders since 1924. Used for mixing doughs, powders, creams, batters, pastes, sludges, slurries and granules for all industries, Winkworth supply mixing machinery all over the world. Their product range includes: Z Blade, Extruder, Ploughshare, Twin shaft, Ribbon, Double Cone Blenders, Paste Feeders, Process Vessels, Homogenisers and vacuum dryers for use in a wide variety of industries. All their industrial mixers are designed and wholly made in the UK and can be manufactured to suit any ATEX requirements, include CE markings and are manufactured in accordance to their ISO 9001 accreditation.