The company, based in London, first acquired a Stealth Gravity metal detector for its products in 2013. “We installed a further line and wanted to obtain the same level of reliability and accuracy,” said Levantine’s managing director David Danil.

“We are BRC (British Retail Consortium) certified,” he underlined. “As a part of that, we have HACCP (Hazard Analysis and Critical Control Point) assessments, with metal contaminant detection high up on the list of control points. Sensitivity levels are also hugely important, and the Fortress equipment exceeded those requirements too.”

From a US perspective, BRC is not as widely recognized as in the UK or Europe. “But we have satisfied the key requirement for importers into the US, which is to register with the Food & Drug Administration (FDA), which controls all food safety matters,” said director at Levantine, Laura Polanco. “As a part of this, we completed a Food Safety Plan, which is a standardized format for HACCP.” This assessment again included careful scrutiny of metal detection systems.

While different varieties of nut still account for the majority of Levantine’s volume, seeds are becoming an increasingly important part of the business.

As David explains, the company caters for retail portion packs, including own-label products for many of the major multiples. Yet, the majority of its business involves the bulk supply of nuts and seeds to other food processors, including snack brands, chocolatiers and ice cream manufacturers. Bulk bags are filled in weights of 12.5kg, 15kg, 25kg and even 1 ton.

Laura adds: “Currently, we don’t supply retail packs ourselves to US customers. But we supply in bulk to different end users in North America, and these include producers of retail nut packs. We supply across our whole range of bag sizes, but the 12.5kg sack is our most popular bulk bag.”

Regarding the new metal detector, a key question for Levantine was the speed and precision of the reject system, which is clearly a critical issue with valuable free-flowing product in freefall. It is vital that any contaminant is accurately targeted and removed, but this needs to happen without removing excessive amounts of uncontaminated product with it.

“In terms of the reject mechanism, we knew that this system did the job for us,” said David. “The speed is adjustable via a pressure-reducing valve, depending on the weight and speed of the product.”

The need to factor in ‘product effect’ is important in many food categories, including nuts and seeds, especially where salt, oils and other seasonings can mimic the presence of metal contaminants. “The impact of this ‘wet’ product effect has been minimal for us with the Stealth Gravity detector,” said David. “The machine settings can be adjusted to read the product accurately.”

He added: “Typically, we’re only likely to get a false reject where there’s a clump of product, salt or herbs, for example. It’s not a big issue for us.”

FITTING AROUND FACTORY FOOTPRINT

Levantine operates a busy manufacturing site in Hayes, West London. Specializing in baking, caramelizing and seasoning, the company was founded in 2003 and produces in excess of 10 tons of edible nuts and seeds daily.

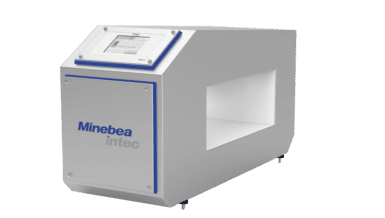

To save on space, the Stealth metal detector is located midway between the first floor of the Levantine factory and a mezzanine. It is controlled from a remote panel at operator level, with product falling from a hopper to the weighing and bagging station below.

Stealth offers the high sensitivity which comes with Digital Signal Processing technology, allowing the detection of ferrous, non-ferrous and stainless-steel contaminants, even down to the smallest dimensions. Data collection is integral to the system, with Contact Reporter Software collecting all events on the metal detection system helping to ensure HACCP compliance.