Getting the most out of your metering screw feeder investment is a necessity in today’s cost-conscious market. Often only a few powders need to be metered and then only one at a time. With wide variations in bulk density and particle sizes, it’s challenging to get one feeder to work on all products.

Feeder manufacturers can provide different feed screws with smaller diameters to cater for lower feed rates. Aside from the increase in costs, smaller augers in a machine designed for a larger screw can affect product flow and the geometry of the feeder hopper, screw and any product agitation.

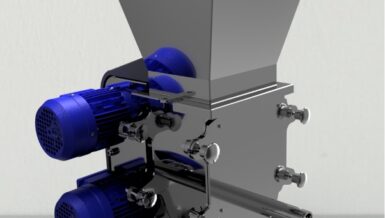

Keeping the Metering Feeder shape and arrangement as initially designed is the best approach. To achieve a broad dynamic feeding range with varying types of powders, a new approach is needed for the auger, and it’s drive system.

The rotational speed of the auger is now the only means of controlling the feed rate or batch quantity. Unparalleled control of speed and torque can be achieved by incorporating servo motors into the auger drive. Speed ranges of 150 to 1 are typical and often exceeded, constant torque and in-built rotational feedback encoders ensure the auger rotates precisely every turn at every speed setting. Pulse feeding of products can be timed to the millisecond and is repeatable on every batch.

When using the servo’s ability to run at extremely low speeds, powders can sometimes be delivered in pulses as the flight of the feed screw passes the end of the feeders delivery tube. Increasing the number of flights on the auger produces a more constant flow of product. Multi-start augers, where a second, third or even fourth set of flights are combined onto one shaft can achieve this. Trantec has developed unique manufacturing techniques in-house to produce these augers routinely in a variety of materials.

Trantec’s combination of multi-flight augers and servos motor control delivers improved performance and accuracy.