An Indian zinc mine operator required a mixer with a very large filling capacity. The proven Combimix system with overflow was custom-built by BHS-Sonthofen in this extraordinary size and shipped off to India. Ease of maintenance, implementation of all customer requirements and a local service office convinced the Indian customer to opt for BHS-Sonthofen.

The largest zinc mine in the world is located in India. And when it comes to total zinc production, India ranks among the top 10. To backfill the mines, the operators require high-quality and robust mixing technology with a very high throughput capacity: Overburden and filter cakes, the by-products of zinc production, need to be mixed to a homogeneous mass free of clumping in order to make the mixture as readily pumpable as possible for backfilling.

An Indian mine operator launched an international tender among mixing technology experts to source new mixers for an upcoming plant conversion. BHS-Sonthofen won the contract due to their high-quality, customizable technology and comprehensive mining expertise, and because the German company also has a dedicated sales and service team in India.

BHS-Sonthofen competently implements demanding customer requirements

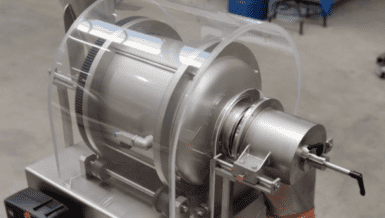

The customer’s requirements were very clear: longer retention time of the material in the mixer and a filling level below the mixing shaft. This means that the mixer required a much larger filling capacity to process the same quantity of mixing material than in the conventional design. Design engineer Sebastian Poppel was responsible for customizing the technology. “These special customer requirements meant that the mixer had to be built for a total capacity of 28,000 liters,” says Poppel, “This made it the largest mixer we’ve ever designed at BHS-Sonthofen.”

The experts at BHS decided that the Combimix system, a twin-shaft mixer of the DKXC series with overflow, would serve as the perfect base technology for the application. According to the customer’s requirements, the filter cake needed to have a long retention time to yield a final mass with maximum homogeneity and as little clumping as possible. In order to optimally meet their customers’ requirements, BHS can draw on a wealth of experience and even carry out extensive tests. “With a throughput of 263 m³/h, we arrived at a retention time of about 137 seconds,” explains Poppel. “During this time, lumps are dissolved to our satisfaction thanks to the high-performance mixing unit.”

A characteristic feature of the twin-shaft mixer from BHS is the three-dimensional mixing method. The turbulent overlap zone of the two mixing circuits generates an intense material exchange, as well as a very high relative movement, thus resulting in a highly homogeneous final product.

In addition to the other requirements, the customer also wanted a product that allowed for high-pressure cleaning and delivered easy maintenance access. BHS-Sonthofen was able to meet these specific requirements without any problems. Production of this largest-ever BHS-Sonthofen mixer was completed in August 2019, and the unit was loaded onto a ship bound for India. Installation in the zinc mine took place at the end of the year under the supervision of BHS experts.