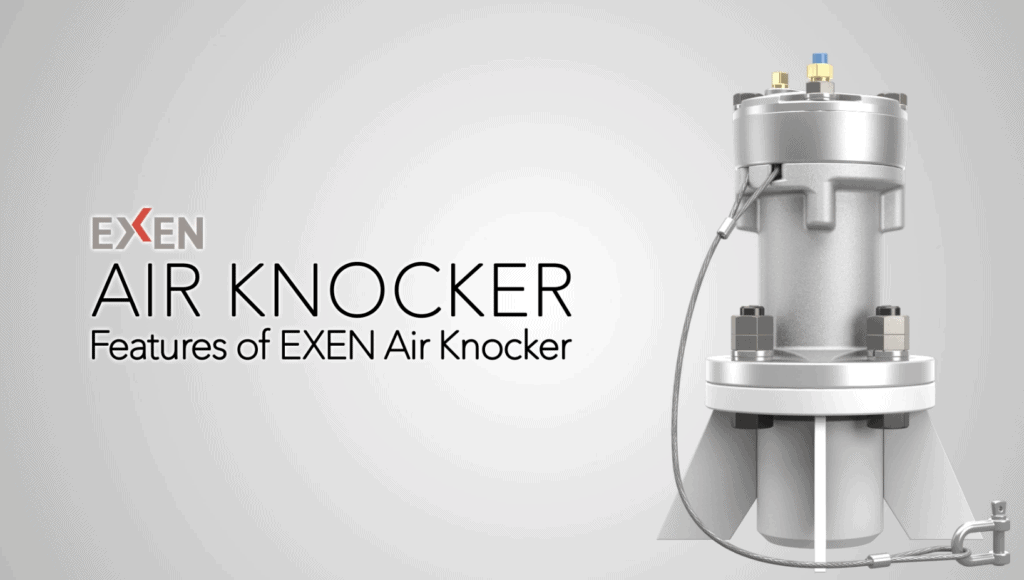

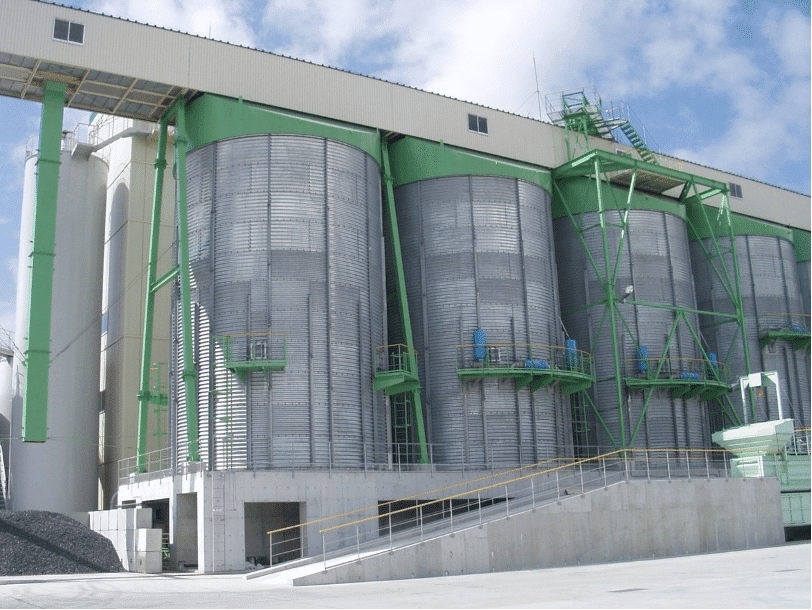

Since 1915, Exen Corp. has been solving clogging problems with its air knocker (impactor). The air knocker continues to perform and provide results on any necessary work type, and is especially effective against fine powders and sticky or clinging materials in the hopper, chute, and pipes.

Knocker will successfully discharge the work even if the content is made of fine particles or sticky materials. If you currently can not solve the problems even uses pneumatic vibrator, electric vibrator, AIR KNOCKER will be successfully able to solve your clogging problems.

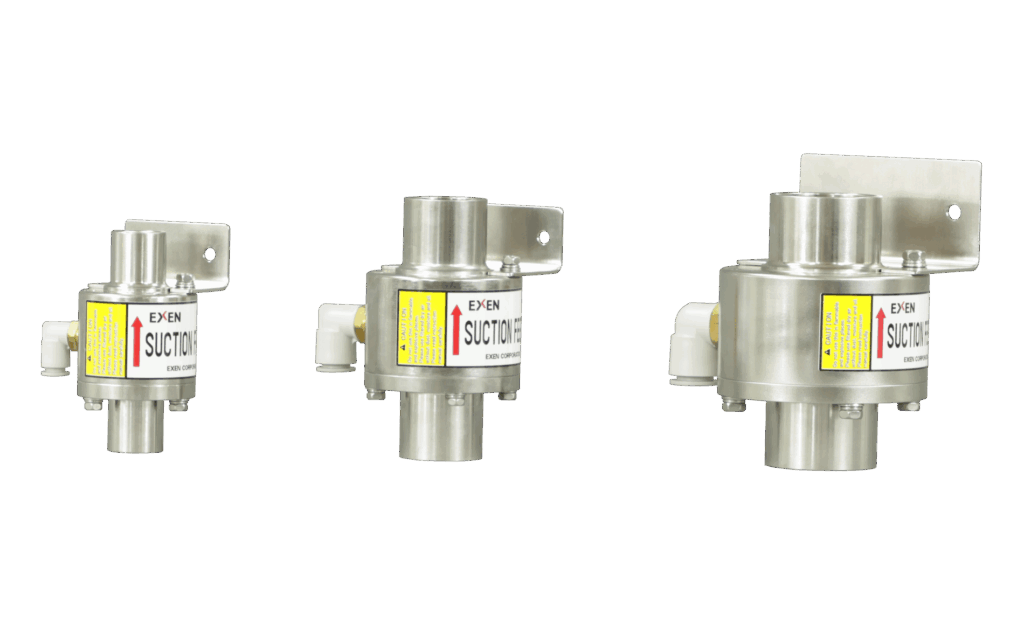

Big impact force of air knocker can be useful for users who have clogging problems. Also, stainless steel made, ferrule clamp spec knocker is perfect for food, pharmaceutical, and chemical industry. It is 100% made in Japan.