The unit features sanitary stainless steel product contact surfaces and is painted using a finishing system designed for use in Food and Beverage processing and is FDA/USDA approved for areas of direct and indirect dry food contact.

High output filling system features an exclusive rotating bag support carriage for maximum filling efficiency and reduced operator fatigue. The bag support carriage and fill head lower to a programmed operator height then rotate for a “reach-free” bag strap connection.

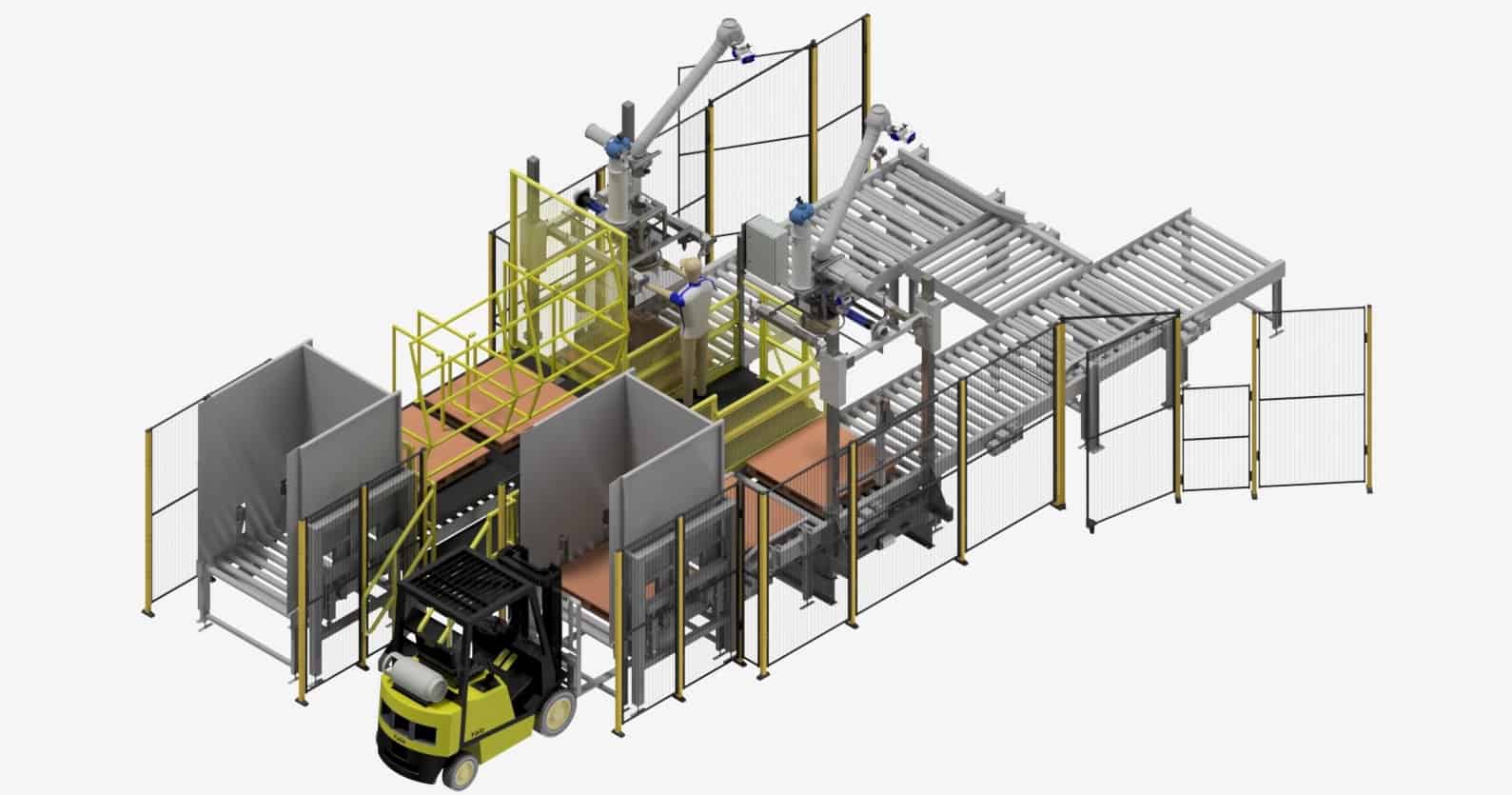

Once the bag spout is sealed, the bulk bag is automatically inflated, filled to a specified weight from the product infeed chute above, and densified. Once the filling cycle is complete, the bag inlet spout and straps automatically release, the fill head raises, and the filled bag can be removed via forklift.

Units are custom designed for your application requirements and can include powered roller conveyors, check scales, pallet dispensers, slip sheet dispensers, and other applicable ancillary equipment.