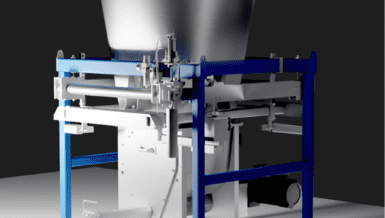

COMBINING MIXING AND SPRAYING IN ONE SOLUTION

Dinnissen developed a mixer capable of spraying phytase, enzymes, and fats onto the pressed pig feed pellets. This process enhances the digestion of gross phosphorus present in the pigs’ system, resulting in a significant reduction of phosphate emissions. Voergroep Zuid was one of the first customers to use a Dinnissen mixer for producing pig feed that helped in reducing phosphate emissions.

“IN JUST UNDER TWO MINUTES, 500 KG OF PELLETS ARE MIXED, THE REQUIRED ENZYMES ARE APPLIED, AND THE PELLETS ARE GIVEN A FAT COATING.”

ELMAR FLACH, TECHNICAL SPECIALIST VOERGROEP ZUID

WHY VOERGROEP ZUID CHOOSES DINNISSEN AGAIN AFTER 30 YEARS

Back in the 90s, Dinnissen was entrusted with assembling the production line for Voergroep Zuid, including supplying the mixer for the line. Now, after about 30 years, the mixers are due for replacement. Elmar Flach, a technical specialist who has been with Voergroep Zuid since 1995, shares:

“Our oldest mixer was installed in 1992, and eventually, three more mixers were added. When the time came to replace the mixers, we really didn’t consider any other option than Dinnissen. While the mixers from Dinnissen have of course advanced since the early 90s, Dinnissen still retained the old designs and was willing to replace our mixers on a one-on-one basis. This way we didn’t have to replace our top and bottom bunkers and we only had one day of downtime. Speed is therefore definitely a reason why we opted for Dinnissen again.”

“WHEN THE MIXERS NEEDED REPLACEMENT AND DINNISSEN COULD DO A ONE-ON-ONE REPLACEMENT, WE REALLY DIDN’T CONSIDER ANY OTHER OPTION THAN DINNISSEN.”

ELMAR FLACH, TECHNICAL SPECIALIST VOERGROEP ZUID

1.5 MILLION TONS OF FEED PROCESSED BY A SINGLE MIXER

“Our calculations indicated that about 1.5 million tons of feed have gone through each mixer over the years. They’re simply good mixers. The pellets are first compressed and then pass through a cooler to the waiting bunker above the mixer. When the upper bunker holds 500 kg of product, the mixer is filled and the mixing process can begin. In just under two minutes, 500 kg of pellets are mixed, the required enzymes are applied, and the pellets are given a fat coating.”

The new mixers do not make Voergroep Zuid’s line significantly more efficient per se, as they’re essentially the same mixers delivering the same results. “However,” Elmar adds, “One convenient aspect is that we now have four identical mixers. This is particularly beneficial when it comes to spare parts, which are always necessary. Now we have a stock of parts that can be used for all four mixers.”

“OUR CALCULATIONS INDICATED THAT ABOUT 1.5 MILLION TONS OF FEED HAVE GONE THROUGH EACH MIXER OVER THE YEARS. THEY’RE SIMPLY GOOD MIXERS.”

ELMAR FLACH, TECHNICAL SPECIALIST VOERGROEP ZUID

A STRONG PARTNERSHIP

“The mixer from 1992 was smaller than the other mixers, which meant more adjustments had to be made for its replacement. We broke open the floor ourselves on Saturday and shut off the electricity so that Dinnissen could commence work on Monday. The first batch of product passed through the new mixer on Wednesday evening. The mixer did pause briefly on Thursday for final touches, but from then on, we were back to full production capacity. Despite contemplating a project delay due to our extensive production schedule, we made the choice to persevere. Looking back, we are delighted with the outcome of our decision. We’re still busy with production, and thanks to the additional manpower and hours, we were able to swiftly replace the mixer.”

“I can’t immediately point out anything that didn’t go well or suggest areas for Dinnissen to improve. Everything just ran smoothly. They always provide clear drawings, ensuring a clear understanding of what to expect. The collaborative planning process proceeds seamlessly, and we’ve had excellent experiences with their on-site technicians. They’re simply a reliable partner located conveniently nearby.”