What are Ribbon Mixers?

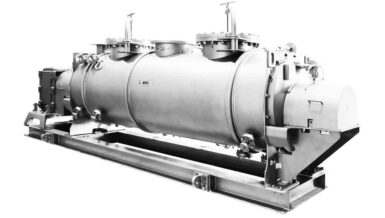

Ribbon mixers are a type of industrial mixer that are commonly used for mixing dry powders and granules. They feature a long, horizontal trough with a central shaft that has two or more helical ribbons, or agitators, mounted on it. The ribbons rotate at different speeds, which causes the materials in the trough to be pulled in different directions. This results in a thorough mixing of the materials in the mixer.

What are Single Shaft Fluidized Zone Mixers?

Single shaft fluidized zone mixers are a type of industrial mixer that are commonly used for mixing wet and dry materials. They feature a long, horizontal trough with a central shaft that has an agitator that has paddles mounted on it. The difference is that in a ribbon mixer, the mixing is done below the shaft and the product’s or ingredient’s weight plays a role in a slow mixing process. In a single shaft fluidized zone mixer the mixing is done above the shaft, in the void space of the trough, and the product’s weight is not an issue. This creates a very quick & efficient mixing.

Which Is More Efficient?

When it comes to efficiency, single shaft fluidized zone mixers have several advantages over ribbon mixers. For one, they are better suited for mixing wet materials. The paddles in the trough help to break up any lumps, bumps, or clumps or agglomerates, which results in a more uniform mix. A chopper can also be used. Additionally, the fluidized zone created by the mixer helps to prevent material buildup on the walls of the drum, which can slow down the mixing process.

Another advantage of single shaft fluidized zone mixers is that they require less power to operate. The fluidized zone created by the mixer helps to reduce the amount of friction between the materials and the walls of the trough, which means less energy is needed to mix the materials.

In conclusion, while both ribbon mixers and single shaft fluidized zone mixers have their advantages, single shaft fluidized zone mixers are generally more efficient for mixing materials. They are better suited for mixing wet materials, require less power to operate, and can help prevent material buildup on the walls of the mixer.