To cope with these needs, Penta has developed and manufactured Spheriko, an innovative loss-in-weight feeder featured by quick and easy connections to make the dosing process simple and easy.

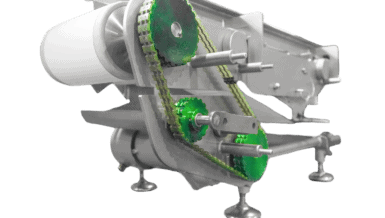

More specifically, it handles any kind of ingredient in powder forms such as flour, sugar, or granules as hazelnuts and almonds grains. Spheriko is extremely accurate during the whole production process, thanks to its strong spherical arch breaker and the digital load cells. In particular, the wide loading hopper and the hemispherical resistant bridge breaker ensure ease of movement to all materials. Furthermore, the feeding of powders is extremely precise and accurate thanks to the digital load cells that dose also micro-ingredients, both automatically and manually.

The loss-in-weight feeder completely made in stainless steel can be easily dismantled and cleaned by line operators without the assistance of the maintenance team, achieving relevant savings in terms of time and resources. This is allowed by quick couplings which guarantee complete cleanliness of components that can be washed in a separate area, in case of deep cleaning.

Several types of screw conveyors are available, according to the product to dose. Spheriko capacity can vary from a minimum of 30 kg/h to a maximum of 1,000 kg/h, for a wide range of customizable solutions.

Spheriko is available also in special configurations, including an innovative barcode system for raw materials tracking. By using the barcode reader, the operator through a monitor can easily identify which are the hoppers that have to be filled in. In this way, there is no human error and no contamination of ingredients, and the correct amount of each ingredient of the recipe is guaranteed.

Barcode reader’s feature allows traceability of all ingredients lots, from the storage position to final recipe enabling the user to identify what material lot was used in a certain time.