But even the dust of products such as fertilizers, rubber, tobacco, spices and many other substances can cause explosions. Therefore, when processing such products, conductive big bags are widely used. For these special type of big bags, grounding is required to prevent ignition due to electrostatic charges.

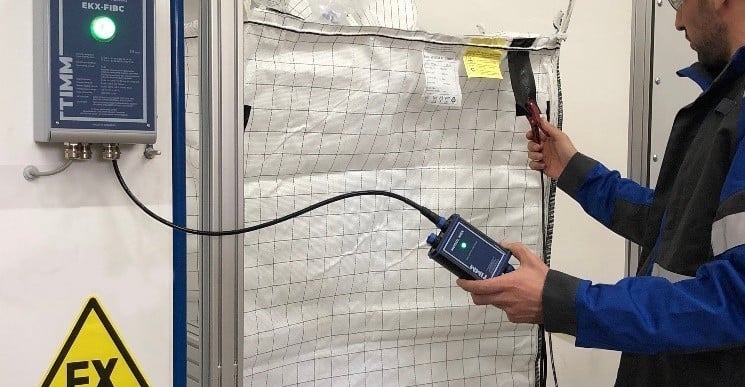

To improve the safety during big bag processing operations, TIMM has developed the grounding control device EKX-FIBC. With its active monitoring of the grounding connection via two grounding clamps and the unique object recognition the device ensures a failure- and tamper-proof grounding.

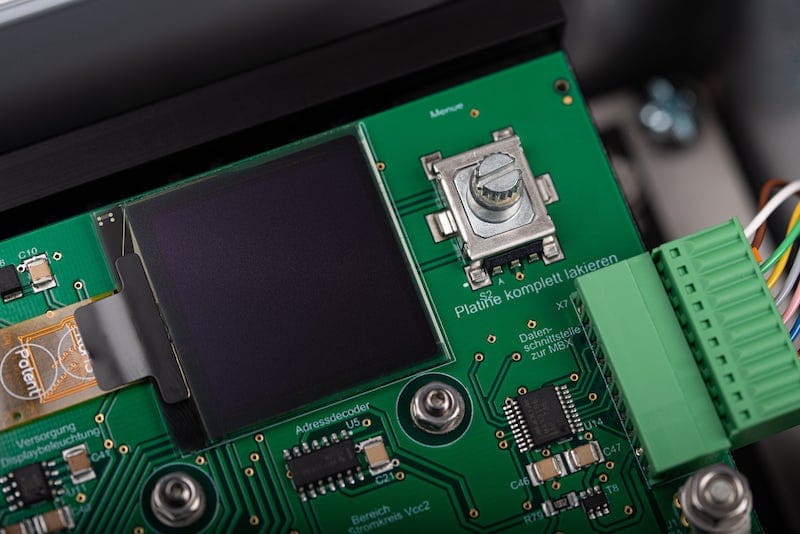

The internal plain text diagnosis-display and the cable quick couplings stand for easy handling during installation, operational use and maintenance. The device gets mounted stationary at the FIBC filling machine and is able to supervise up to two big bags at the same time. A filling release is only given, when the connected FIBC is properly recognized by the object detection and, in addition, safely grounded. The device can also automatically shut down the (un-)loading process in case of an unsafe situation to re-establish a safe status.

You want to experience the modern way of monitored grounding by yourself? Come and visit us at the POWTECH from 30.09. – 01.10.2020 in Nuremberg, Hall 1 Booth 1-449. Alternatively, give us a call +49 (0) 40 248 35 63 – 0 or mail us info@timm-technology.de. We are looking forward to hearing from you!

You can find further information about our company and products at our website www.timm-technology.de/en and at our LinkedIn profile https://www.linkedin.com/company/timm-technology/