U.S. Silica is a leading sand supplier and their state-of-the-art products are now matched by equally modern aeration devices for their storage silos. “Five years ago, we embarked on a project to convert our screen style air pads to a better method of aeration. The pads were breaking off and contaminating the material requiring shutdowns, “explains Tom Proctor, production manager at the company’s Ottawa, IL mine, “I discovered the Solimar aeration system and began a replacement program and I haven’t regretted that decision.”

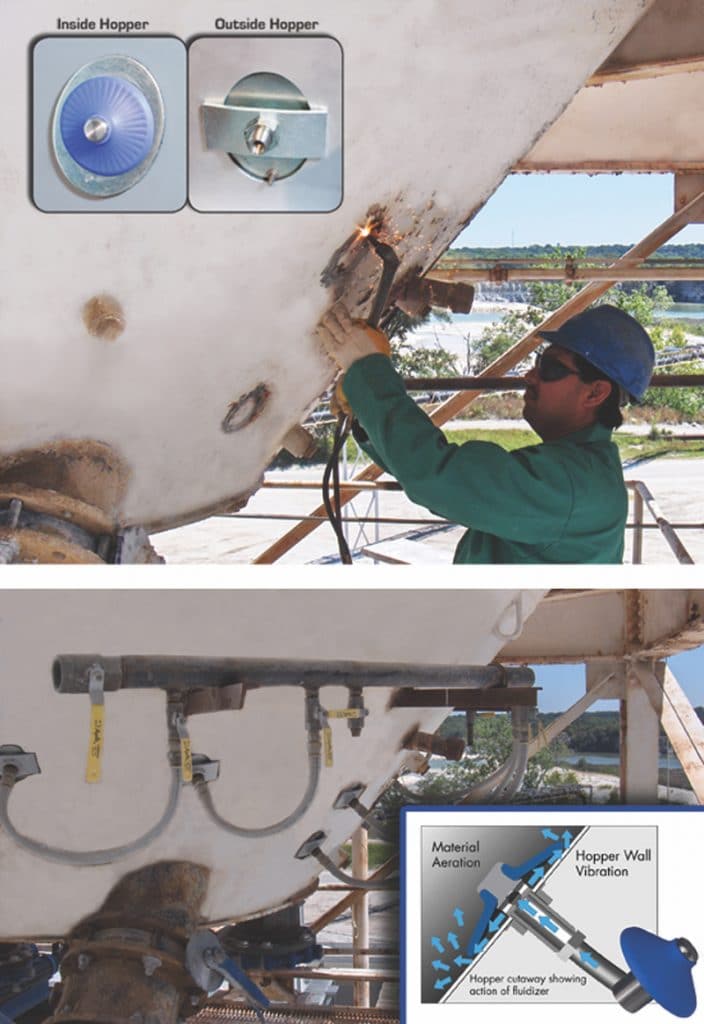

In order to maintain the failing air pads in the 120-ton silos, workers were required to enter the silos. “Since we have installed the Solimar disk-type aerators, we haven’t had to send anyone into a silo for aeration maintenance,” according to Proctor. Using technical assistance from Solimar, the company decided on eight aerators per silo. These were easily installed without entering the confined space using the Solimar EZ-IN system.

“We haven’t had to replace any of the disks in five years so maintenance has been nothing compared to air pads, “explains Proctor, “That is a savings of $8500 in maintenance alone.” He also praised the low-profile aerators for their excellent flow characteristics and wear resistance with “very abrasive” sand. Proctor adds, “Keeping our employees safe, and seeing a cost savings is a great achievement.”

U.S. Silica is dedicated to staying on the cutting edge of technology and their use of Solimar aerators is another step in that direction.