The dosing tool is constituted by a horizontal screw. Different types of screws are available, they are interchangeable, to be chosen according to the dosing product’s characteristics. The carpentry-made dosing screws can have different shapes, obtained using square or round section spirals and flat helix, also with welded central shaft. The dosing screws can be manufactured with different pitch geometry: square, long, or reduced and with single or double principle.

Machined out manufactured dosing screws are also available with full flight profile, lowered diameter, or concave geometry. Also in this case it is possible to have different pitch geometry types: square, long, reduced, with single or double principle. The front side of the doser from which the product comes out has an outlet tube, which contains the terminal part of the dosing screw. The tube is flanged to the body of the doser and it can be removed to allow the dosing screw dismantling. The dosing screw is fixed to the gear motor shaft through a threaded or bayonet connection.

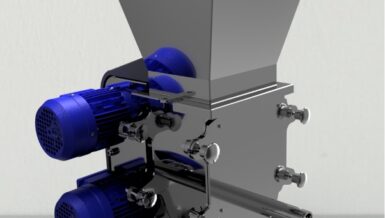

The body of the doser has a trough shape with a specific geometry suitable to house both the dosing screw and a horizontal agitator. This last action is fundamental to avoid the formation of bridges that can occur mostly with compact and poorly flowing products. The horizontal agitator also feeds the dosing screw regularly and constantly, to have good dosing repeatability.

There are different horizontal agitator models to choose from according to the product characteristics. The body of the doser is completely openable removing the front flange which is tightened with nuts and bolts. In this way, it is possible to have access to the dosing screw and to the horizontal agitator that can be easily removed to be cleaned and sanitized.

Are also available versions equipped with knobs and safety microswitch, instead of bolts and nuts, that allow opening the body of the doser more quickly. This arrangement is useful when the cleaning operations are frequent. Vertical T spouts complete the set of this kind of dosers. They are mounted at the end of the front outlet tube to vertically guide the product from falling down while dosing. Discharges equipped with automatic plug, slide, or butterfly valves are also available. These devices have the function to intercept the product while falling down. In the batch dosages, they are particularly suggested to obtain maximum accuracy. The transmission groups that move the dosing screw and the horizontal agitator are constituted by worm-type gearboxes and three-phase electric motors.

The shaft mechanical seals are made with shielded bearings and dust-tight rings available in various materials such as NBR, SILICONE, PTFE, and VITON. Air flushed sealing groups are also available for the hardest cases. Atex certified motors are available eventually equipped with a temperature probe and anti-condensation heating devices when it is requested.

The transmission groups can be equipped with a device for detecting the direction of rotation of the dosing screws and of the horizontal agitator. The device is made of an inductive sensor and a flap keyed on the slow shaft of the gear motor. Everything is protected by an aluminum restraint box with transparent polycarbonate sight glass.

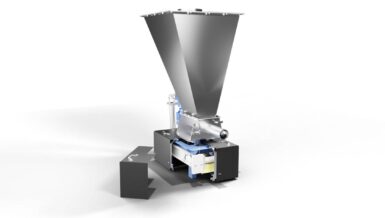

The entire doser range CH, CHW, and CHY is constituted by 12 standard sizes that allow covering a range from a minimum of 0,1 Kg/h to a maximum of 10.000Kg/h. It is possible to associate to the dosers a wide variety of standard loading hoppers with different capacities. The hoppers can have a polygonal or truncated conical, symmetrical or skewed shape and their design ensure a correct outflow and complete emptying even with poorly flowing products.

The hoppers loaded manually have a completely removable lid or semi-openable with hinges. Inside it there is a safety grid that protects from the risk of contact with moving parts of the doser and prevents the accidental access of foreign matter that could damage the doser. The hoppers automatically loaded have bolted lids with a round inlet and a vent socket equipped with a bag in polyester filtering fabric sleeve. As for accessories of the hoppers, there are level sensors, to detect the presence of a product, and pneumatic vibrators or moto vibrators to prevent the formation of bridges.

In the gravimetric version, the doser can be installed on a proper platform scale(CHW) or hung to load cells with its hopper (CHY). The load cells are off-center or flexion type, made in aluminum or in stainless steel with protection grade up to IP67, available also with Atex certification when requested. The most used construction materials are stainless steel Aisi 304 and 316L, but it is also possible to provide carbon steel on request.

The surfaces in contact with the product can be easily pickled or mirror polished in case of poorly flowing products. It is possible to have certifications of the contact materials on request. The external surfaces are satin finished 180 mesh. It is possible to have them glass bead blasted or electropolished on request. The gaskets are made in dust-tight rubber, such as SBR or NBR. They are available also with FDA certification on request.

Both volumetric CH and gravimetric CHW and CHY dosers can be Atex 21/22 and Atex 21/21 certified if required. Electrical control panels can also be supplied including software specifically designed according to the requested functionality.