Overcoming the problem of standard mild steel bolts being drawn to the fixed magnets and increasing service life.

The challenge:

To supply non-magnetic elevator bolts for magnet conveyors that are removing metal and ferrous tramp materials from crushed recycled concrete.

The customer, Allstate Conveyors, who manufacture large “Mag Belts” for a number of magnetic separator OEM’s in Australia.

Were initially utilizing conventional conveyor belting that was either spliced endless or joined with belt fasteners complete with an overlay of 12mm thick 40 durometer soft abrasion resistant rubber.

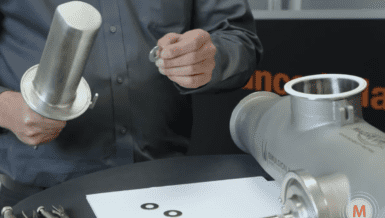

Which is then bolted onto stainless steel pressed wear plates in the centre of the belt. The plates needed to be bolted with non-magnetic fasteners. The recess in the plates protect the heads of the bolts from being worn or broken off during operation.

The solution:

The 4B solution that was offered was to utilize 304 grade stainless steel fanged bolts, which have a significantly reduced magnetic resistance.

This in turn almost completely eliminated the issues caused by standard mild steel bolts of being drawn to the fixed magnets.

Which would cause excessive wear and reduce effective service life considerably.

Results:

The higher-grade bolts have provided a performance benefits, that has significantly exceeded previous components service life.

This has in turn also provided operators with costs benefits not only on their equipment but their operational availability.

The fanged elevator bolt is characterized by two sharp teeth that are intended to penetrate the carcass of the elevator belt.

Once the teeth penetrate the belt, they help keep the bolt from spinning which easily allows the lock nut to be tightened.

4B’S ENGINEERING & SUPPORT SERVICES

At 4B, engineering services and support have always been at the core of the business, and just as important to the business as the products themselves.

Whether it is a technical problem on an existing installation or advice needed for a new installation or an upgrade of a facility, 4B engineers thrive on the challenge of providing innovative engineering solutions.

4B can also assist with inspection of equipment, maintenance as well as testing and commissioning services.