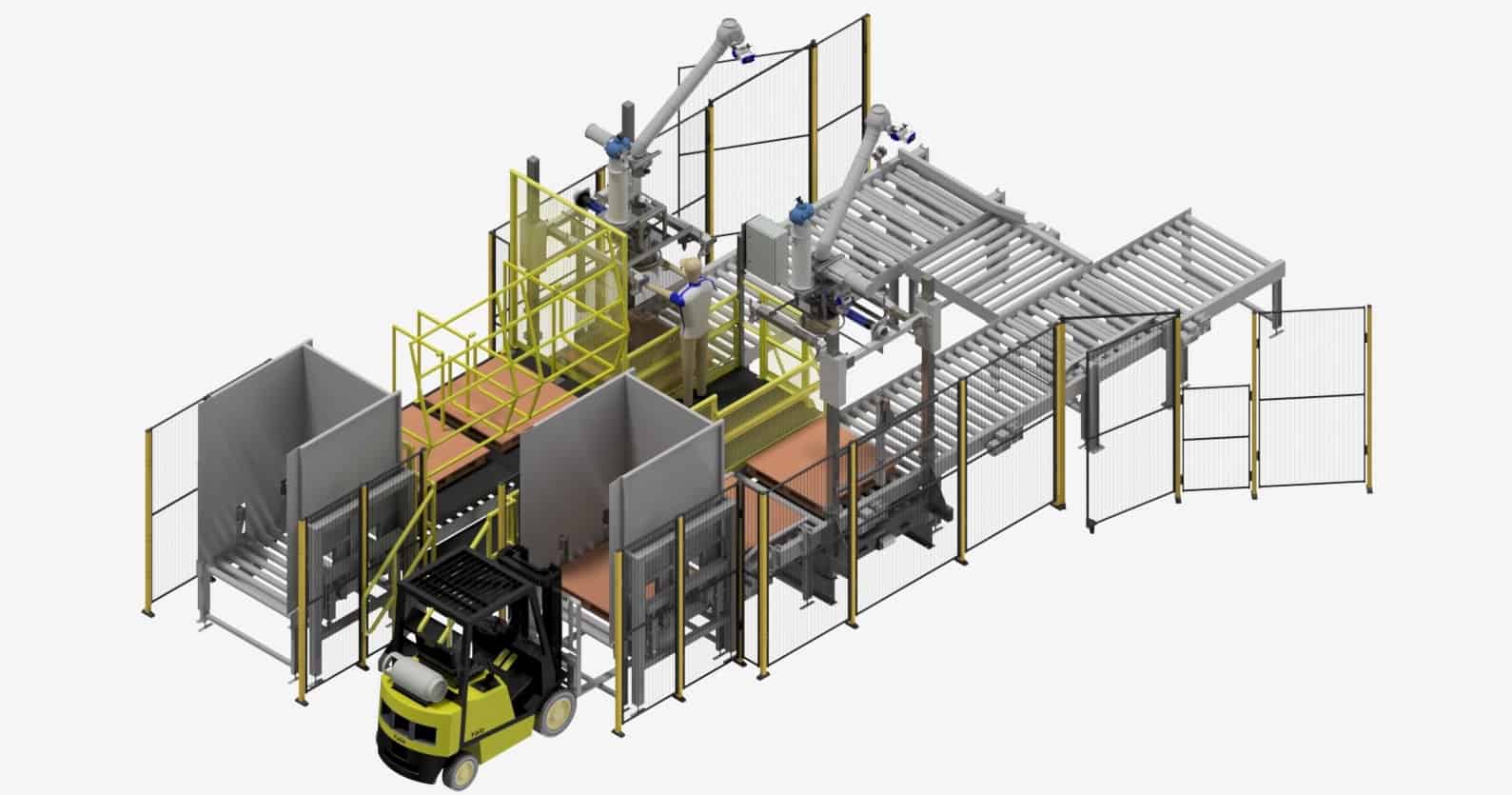

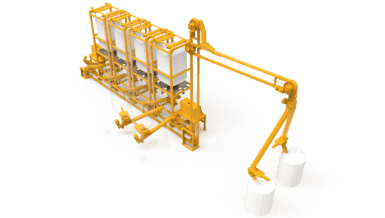

The system consists of a high capacity dosing system (twin screw conveyor for high accuracy), a bag filling & weighing system, and an in-line magnetic system.

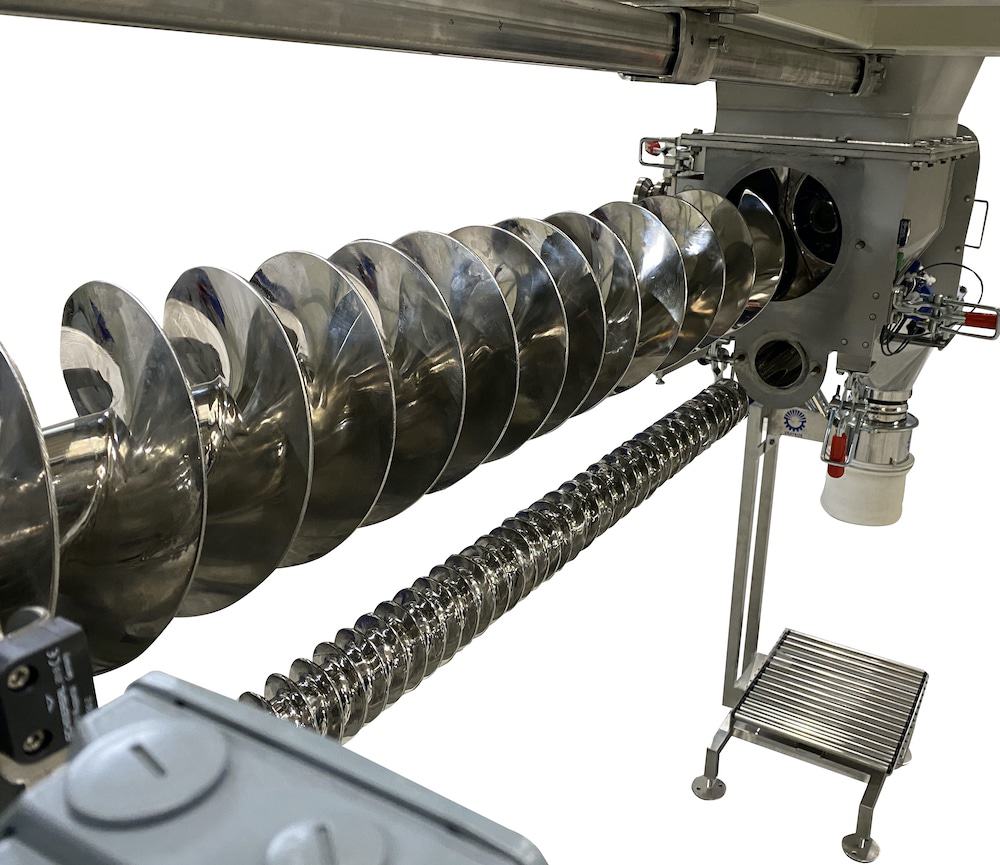

High capacity dosing: twin screw conveyor for high accuracy

- Stainless Steel 316L

- Fast and dribble flow for both a high product throughput and accurate dosing

- Retractable screw shaft and fast removal of screw conveyor internals, for easy cleaning

- ATEX Zone 22 certified: safety at the highest standards

- Semicircular ends for the screw wings

- Seamless shell with a mirror-polished internal surface

- Finest treatment of the outer surface with glass-blasting

Bag filling & weighing system

- Adjustable frame

- Inflatable bag clamp for different bag sizes

- Spare frame adaptor for small bags and containers

- ATEX-certified high accuracy Load Cells and Junction boxes

Magnet system

- Stainless Steel frame and magnets

- Mirror-polished

- Magnetic bars 11000 Gauss each.

- Retractable magnets for fast removal and easy cleaning

Processed materials

Bakery Powders (Flour, emulsifiers, powder sugar, etc.)