With activities in the most diverse sectors, both knowledge and an extensive product range were built. “Our robustness, quality and reliability are highly valued in Typhoon” says Kris Devidt, managing director of Typhoon. “With this realization we achieved a very high customer satisfaction, and we are very proud of that”.

For the trading, sorting and cleaning of linseed, Typhoon built an dust extraction system that was placed on top of the roof of the factory. This gave the big advantage that no additional area on the site had to be provided. The installation consisting of three filters has a total of 180,000 m³/h of dedusting capacity. The installation was built according to current Atex-and safety regulations. The extracted air can be fully recuperated in the building to avoid heat losses and drafts.

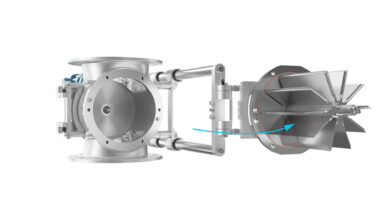

The filters were developed with efficient compressed air cleaned puls-system and seamless filter sleeves. This ensures a risk-free operation due to the specific nature of the dust. Because of their unique construction and pre-separation, the filters are suitable for continuous operation.

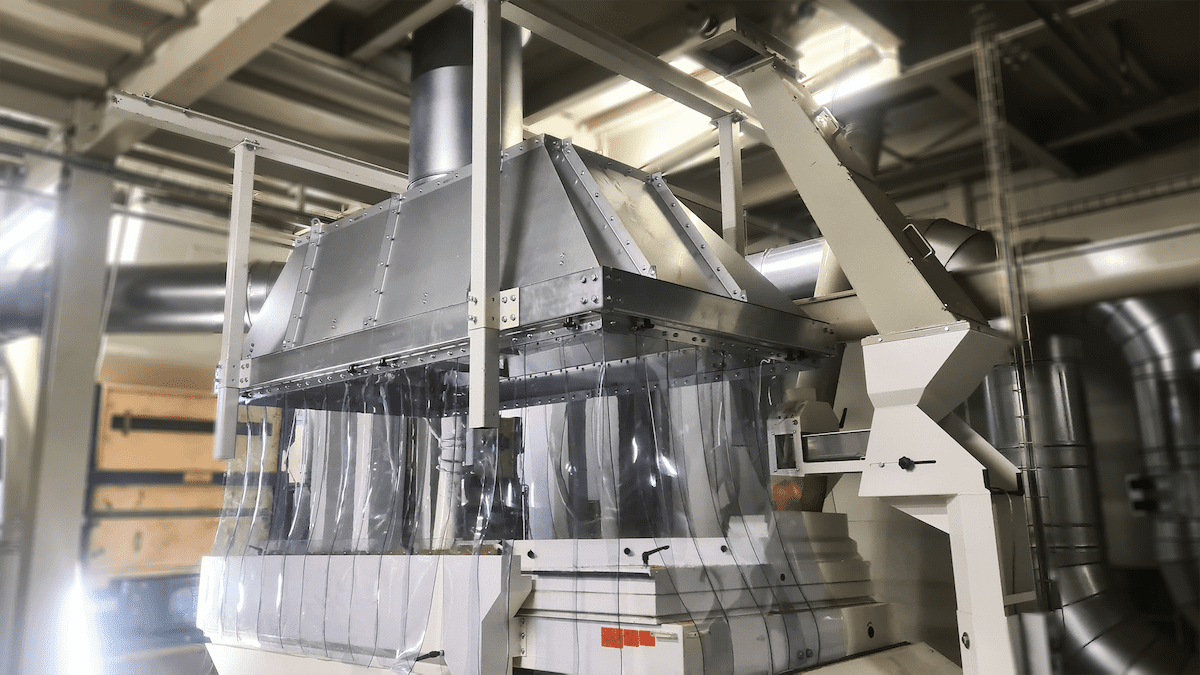

Not only the new screening and cleaning production lines were equipped with the necessary hoods and dedusting. But also the existing production lines were converted to the new dedusting installation.

The extraction fans were installed inside so that inspection and maintenance can be carried out very easily and safely.

Both filters, fans, ductwork, galvanized steel structure and platforms were installed by Typhoon within the agreed delivery time.