International safety standards and guidelines legally require explosion mitigation and protection techniques to be put in place, however there is no “one size fits all” answer and the most effective solution will often be application specific.

Explosion protection systems are broadly divided into two groups:

- Passive Explosion Protection

- Active Explosion Protection

Passive explosion systems rely on the pressure generated during the early stages of explosion development to cause a mechanical movement. For example, explosion relief vents open at a predetermined pressure to relieve the explosion pressure; the opening is caused by the explosion pressure itself.

In contrast, active explosion protection systems rely on a detector of some kind – for example – pressure or optical, which then triggers an electrical circuit to cause the rapid actuation of an explosion protection device, such as an explosion suppressor.

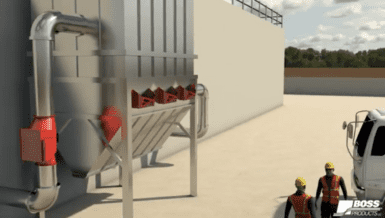

When considering what technique works best for your process, it’s entirely application specific. While passive systems are more commonly used due to low cost, relative ease of design application and low maintenance, they do not mitigate flame within the process which can lead to post explosion fires, and both flameless and standard venting require exclusion zones in the vicinity of the vent portal to protect personnel.

Active systems – in particular suppression systems – mitigate both pressure and flame within the protected plant, and also contain the explosion. They do however require regular maintenance to verify system reliability and reduce the risk of non-explosion related activations.

Depending on the process and equipment being protected, elements of both active and passive devices may be employed to make up a comprehensive system solution.

Here, Burke Desautels of IEP Technologies explains the key differences between active and passive industrial explosion protection devices and how they may be used in combination to create a comprehensive explosion protection system.

IEP Technologies offers leading-edge explosion protection solutions to customers worldwide and can assist with all stages of the selection process – from materials testing, active and passive explosion protection systems, spark detection and extinguishing, through to on-going service and support. Contact IEP Technologies today to start the conversation about your explosion protection needs.