In almost every production facility, individual plant components are interconnected by means of pipelines. The purpose of explosion isolation is to seal these pipelines in the event of an explosion to prevent the propagation of pressure and flames, thereby protecting the adjacent plant components. Precompression and flame jet ignition increase the severity of the explosion in the connected vessels. This leads to secondary explosions that can cause even more catastrophic damage.

Isolation systems prevent an explosion from propagating, thereby reducing the effects of the explosion to a minimum. Adjacent system components are optimally protected.

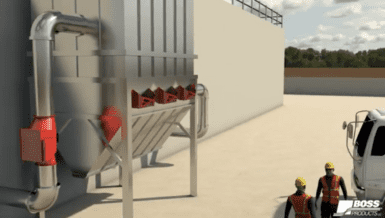

Explosion Isolation System Q-Bic

The explosion isolation system Q-Bic registers the emerging explosion and extinguishes the developing explosion flames within milliseconds by applying the extinguishing powder. The extinguishing powder is optimally distributed in the pipeline via a nozzle system and guarantees reliable isolation. The chemical barrier is particularly well-suited to applications in elevators and spray dryers.