Zoning

When the air (with low or high dust load) enters the filter, some of the fine dust particles will settle on the filter elements. The cleaning of the filter elements is usually done by air pulses on the filter elements, which creates a dense cloud of very fine dust per cleaning cycle. Thus, an explosive dust cloud can be expected on a regular basis, at least in a part of the filter housing. According to the zone definitions in the ATEX directive 1999/92/EC (ATEX153) this means a zone 20 situation.

Consequently, the housing of most dust filters must be regarded as zone 20. Of course, there are exceptions to this general rule, for example in the case of mechanically cleaned dust filters.

In the clean airline of the dust filter, the section of the line behind the filter elements, there is usually no or very little dust. An explosive dust cloud will therefore rarely or never be created there. Therefore the clean air pipe can be considered as a zone 22 situation.

Acceptable risk

According to ATEX153 equipment in a zone 20 must be certified as cat 1D, related to ATEX directive 2014/34/EU (ATEX114). According to ATEX114, the requirements for cat 1D equipment are that ignition sources may not arise even in the event of two independent fault situations. This requirement must also be used in the risk analysis to achieve an acceptable safety basis: for a zone 20 situation in a dust filter, prevention is only sufficient if no ignition sources can be expected even in the event of two independent fault situations.

Example: if a (conductive) filter element is not earthed, it may be charged and cause spark discharges towards the filter housing. To prevent such discharges, the element must be earthed. But even then, such discharges must be taken into account: a filter element is forgotten or can come loose. A spark discharge should at least be considered a rare fault situation. But even such a situation is not acceptable in zone 20!

Equipment in zone 22 must be certified as category 3D. According to ATEX114 this means that ignition sources may not arise during normal operation. It must be clearly described what can be considered a normal operation.

Explosion protection

The mere purchase of an ATEX-certified filter is insufficient. The certificate only guarantees that the filter itself does not produce any ignition sources. However, ignition sources can also come from outside.

Considering the zone 20 situation, only preventive protection, for example by spark detection and water extinguishing, is insufficient. The dust filter housing can be provided with rupture discs so that in case of an explosion the pressure remains below the design pressure of the filter. Besides, in case of an explosion, flames will develop. It is best to place the dust filter outside in an inaccessible place so that the flames can be safely diverted. If the dust filter is located inside the factory, a flame arrestor can also be installed.

Compartmentalization

The need for compartmentalization or explosion isolation is still regularly overlooked. ATEX-certified dust filters are often found with rupture discs, without barriers on the inlet and outlet. Flames from the explosion can move freely through these exits and still cause a secondary explosion in the rest of the installation.

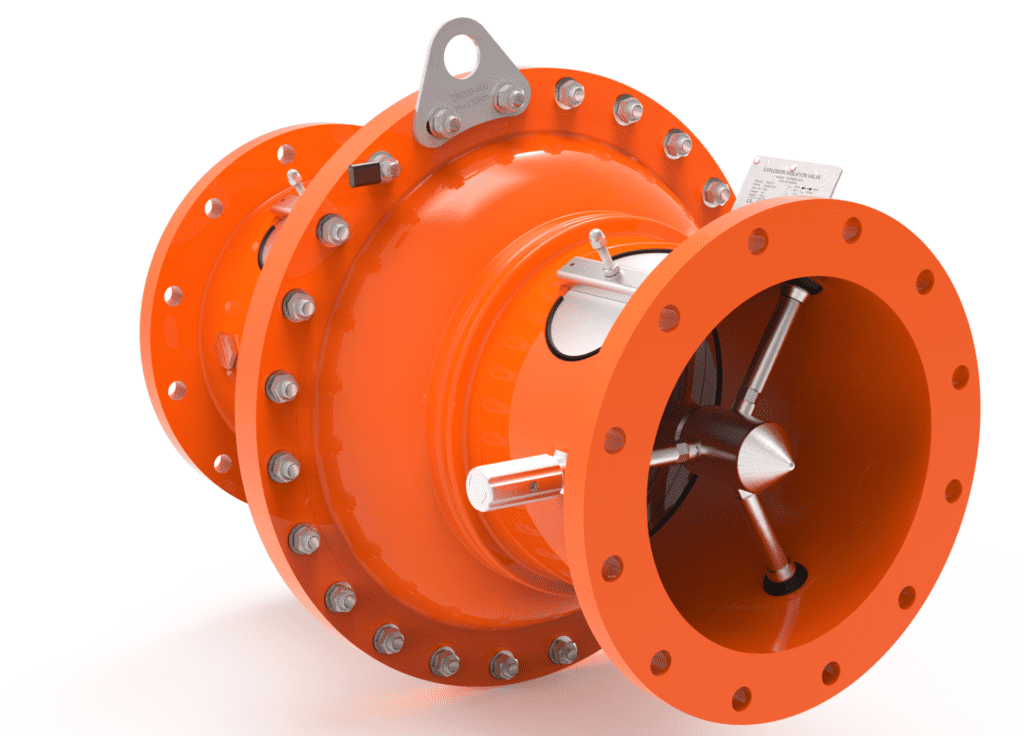

The inlet of a filter is in many cases closed off by an ATEX-approved non-return valve. The NOVEX II locks itself due to the explosion pressure wave. This valve can be placed both horizontally and vertically and is available up to a pipe diameter of 1250 mm. Sometimes a dust filter has several inlets. Then it can be advantageous to place a powder barrier. With one bottle, several entrances can be compartmentalized at the same time.

The outlet of a dust filter is usually fitted with an ATEX-certified rotary valve.

As the clean air line of a dust filter usually covers a zone 22, compartmentalization is not always necessary here. There is little or no dust that can be raised by the explosion pressure. Moreover, the filter elements provide a flame retardant effect. Due to the lack of fuel in the clean air pipe, an acceleration of the explosion flame and consequently a pressure increase in the pipe is very rare. However, this cannot be excluded. If the clean air duct and the fan lead into a safe (non-accessible) zone and are resistant against the reduced pressure, a compartmentation can be omitted. If the clean air duct ends in the factory hall – for example in the case of heat recovery – or in a zone accessible to personnel, the clean air duct must still be compartmentalised, for example with a VENTEX valve. The ATEX certified VENTEX valve locks due to the explosion pressure, even if the direction of the process flow is the same as the explosion direction.

Conclusion

A dust filter can only be considered explosion-proof if both the risk of explosion and the flame transmission to all entrances and exits have been investigated. In many cases, this means providing pressure relief combined with an ATEX-certified disconnection system. StuvEx can help you with the protection of all your dust filters.