This is different for sugar or alcohol, for example. These products can, in the right air/dust concentration (for sugar dust) or air/alcohol vapour, in combination with a static spark of sufficient energy content, result in an explosion.

The electrical charging of a bulk truck and load can take place during road transport and during loading/unloading of the load, a bulk truck can be charged up to tens of kV and give rise to electrostatic sparks up to 100mJ. Whether this energy quantity is sufficient for an explosion depends on the minimum ignition energy (MOE) of the product to be loaded.

For flammable vapours/gases, the amount of ignition energy required to provide ignition (MOE) will usually be < 1 mJ. This relatively small amount of ignition energy required to ignite a flammable gas or vapour means that truck grounding will always be a requirement in that situation in order to minimise the risk of explosion during loading. Compared to flammable vapours/gases, the values of the minimum ignition energy (MOE) for air/dust mixtures are often higher.

A lot of information about the explosion characteristics of products can be found at www.gestis.dguv.de.

And is grounding required for electrically conductive products to be loaded?

Yes, even conductive products can be electrically charged. And when discharging this static charge poses a risk, truck grounding becomes necessary in this situation, too.

How does such a grounding work?

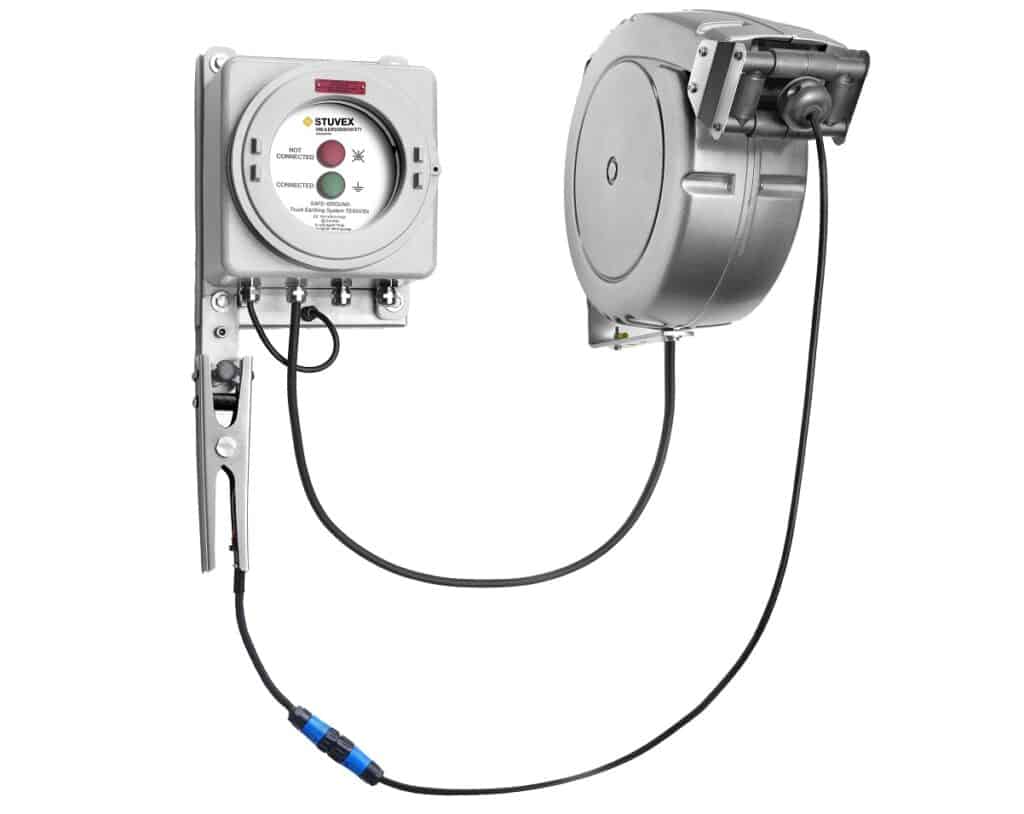

With a single yellow/green earth wire and clamp, you could already make an earth connection. However, the truck grounding systems applied nowadays in an industrial and ATEX zoned environment are subject to more requirements.

- The truck grounding systems must be ATEX certified.

- By means of a measurement (capacitive) the earthing unit can determine whether the connection is on the earthing point of a truck and not on another metal object.

- This ‘forces’ the truck driver to place the earthing clamp correctly on the truck, and thus increases the establishment of a correct (thus safe) earthing connection.

- During the period that the clamp is attached to the earthing point of the truck, the resistance is checked to ensure that it remains sufficiently low. A cable break or bad connection between the earthing unit and the clamp will be immediately detected (a resistance value < 10Ω is recommended). A clear indication on the earthing unit, by means of lights, indicates to the user when a correct earthing connection has been made.

- Potential-free contacts integrated in the earthing unit can be used, for example, to switch on a pump, blower or valve when a correct earthing connection has been made. This creates an automatic start-up condition for safe loading and unloading.

Do these earthing units have to be inspected annually?

As a rule, truck earthing units are not inspected annually for proper functioning; ultimately, they are usually self-monitoring. A check on the proper functioning of the truck grounding system (depending on the type of grounding system) can usually be carried out and recorded by the end-user.

Insurance companies may, however, impose additional requirements on the end-user such as having the earthing system checked by a third party. If the earthing unit is placed in an ATEX zone, it is subject to the periodic inspection of ATEX equipment.

Where can I find more useful information on static electricity?

In the technical specification IEC/TS60079-32-1:2017 “Guidance on electrostatic hazards. This technical specification is primarily written for designers and users of processes and equipment, manufacturers, and test facilities. They are informative guidelines to reduce risks related to electrostatic charging and discharges.