Like the products that make up the VIGILEX range: explosion vents, flame arresters and diverters, STIF has conducted the test campaign for its new non-return valve with the French certification body INERIS. The tests were carried out according to the EN 16447 standard and reinforced by an approach not mentioned in the standard, that of the piping installed downstream of the non-return valve.

Indeed, STIF has designed an innovative valve to meet a series of real needs and in a research and development process in partnership with INERIS. The purpose of this test campaign was to reinforce the knowledge of the behavior of a check valve during an explosion, in conditions as close as possible to the real uses of the product. Also, it was observed thanks to the numerous tests, that the counter-pressure generated downstream of the valve after its closure due to the explosion from the 10 m3 test tank, generated a very powerful mechanical stress and significantly influenced all the technical parameters of the certified product.

The test results highlighted the importance of the real conditions of use of the non-return valves and the current limits of the EN 16447 standard in the test recommendations. Indeed, on the market today, there are many check valves «certified» under conditions that are not sufficiently close to reality and therefore do not adequately protect the installations in which they are installed.

The back pressure observed and illustrated by the yellow curve in the graph shows us that the force exerted on the valve is greater downstream than upstream for a short period (30 ms) between 200 ms and 250 ms, after the valve is closed, then again during the same period between 300 and 350 ms and then between 400 and 450 ms. This back pressure reaches more than 300 mbar while the upstream pressure has dropped to 100 mbar during the first wave.

This series of waves exerted considerable mechanical stress on the check valve. Therefore, STIF had to modify, reinforce and adjust the valve’s lever mechanism, the body and the overall strength of the product to cope with these stresses.

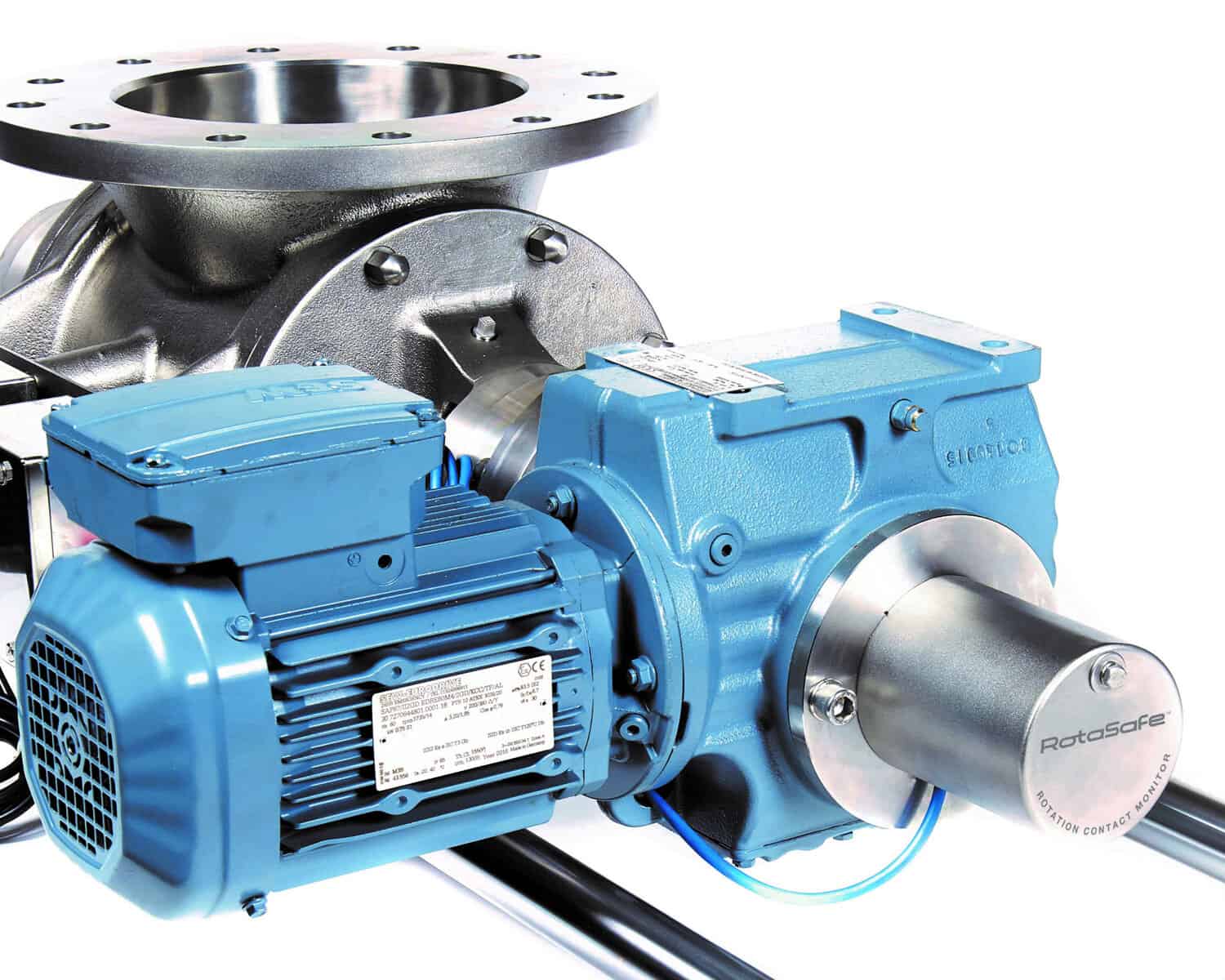

The main consequence of this observation is an increase in the distance between the protected tank and the valve. In fact, all the tests carried out without downstream piping do not subject the valve to this important stress, which is why the distances between the tank to be protected and the valves installed on the market are completely wrong. The VIGIFLAP non-return valve has been designed, tested and certified to protect your applications under real conditions of use. The EN 16447 standard is bound to evolve rapidly following this test campaign.