Many industries worldwide are exposed to the dangers of dust explosions.

Some common examples include:

- Food and Beverage

- Chemical and Pharmaceutical

- Wood Processing

- Power Generation

- And many more….

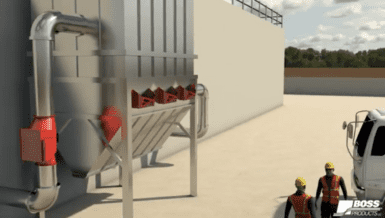

These explosions occur when fine combustible particles, dispersed in air, are subjected to an ignition source within a contained processing environment – for example, a duct, vessel, or dust collector. Ignition can be generated by several factors, including hot surfaces, flames, welding, spontaneous combustion, friction or uncontrolled electrostatic discharges.

The consequences of industrial explosions can be devastating, leading to costly business interruption and plant damage, as well as the potential for employee injuries and even fatalities. Statistics show that the average financial impact of each industrial explosion can be in the millions.

Explosion protection is therefore vital to mitigate this risk, and global safety standards and guidelines legally require explosion mitigation and protection techniques to be put in place. These codes prescribe preventative measures such as process safety engineering, operator awareness training, and effective plant maintenance and housekeeping.

In this video Burke Desautels explains the need for industrial explosion protection and introduces the main techniques for mitigating this dangerous and costly hazard.