Dec Group, at the forefront of aseptic filling technology, is a Swiss-based company operating worldwide that specializes in providing aseptic filling solutions for the pharmaceutical industry from bench to full production scale.

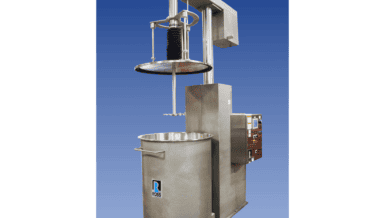

One such solution is the DecFill® LAB, which has been specifically designed for laboratory and R&D applications.

R&D and laboratory scale use

The DecFill ® LAB is ideal for workbench setups but can also be integrated into a glove box for sterility assurance. It is a mobile and compact tabletop unit that can handle a wide range of container types such as Ready-to-Use (RTU) systems, vials, cartridges and syringes.

It features Dec’s proprietary powder filling and/or award-winning liquid BoMa dosing technologies guaranteeing high filling accuracy and no shear stress.

Liquid filling with new unique dosing technology

The patented BoMa dosing technology had been inspired by Boyle’s Law(1) and allows to accurately dose a wide range of products showing characteristics from liquid to viscous.

Let’s enumerate some of the unique BoMa attributes:

- 100% In-Process Control of the dispensed volume, which makes it ideal for dispensing small volumes in an isolator where weighing scales are often performing poorly

- No shear stress exposure, i.e. preservation of product quality, reduced waste by maximized product yield, uniform dispensing, ideal for sensitive suspensions used in molecular biology

- No dead volume re-circulation, ideal for small batches

- Possibility to include decontamination (UV/degassing) and visual control before dispensing

- Collapsing of soft bags (pouches, IV bags, etc. prior filling without disconnection, preventing gas inside the container

- Unlike other peristaltic pumps, no sensitivity to viscosity changes

- No mechanical displacement, i.e. less particle generation (plunger of rotary piston pumps and roller on tube of peristaltic pumps)

- Only one single mechanical device which is a well proven microfluidic multi-port valve

- The dosing chamber can be completely emptied when handling products that easily drip (low surface tension, with long polymeric chains, etc.)

- In vacuum mode, any gas can be added after dispensing for blanketing the container before closing

One of the key features of the DecFill ® LAB is its manual container placement system. This means that an operator can place the product containers manually. It is fitted with automatic check weighing and stoppering capabilities.

With this lab unit, data collection is made easy as it includes a USB download feature. This allows for valuable data to be collected and analyzed for quality assurance purposes and makes the DecFill ® Lab version an efficient tool for research teams.

Another advantage of the DecFill ® LAB is its simple and user-friendly interface and recipe control options via HMI. This makes it easy to operate, even for those who are not familiar with the technical aspects of aseptic filling.

In addition, the DecFill ® LAB may be integrated into various aseptic Dec containment systems such as oRABS and isolators. These options provide additional protection against contamination, ensuring that the sterile product remains uncontaminated throughout the filling process.

Overall, the DecFill ® LAB is an efficient and user-friendly solution for aseptic filling in laboratory and R&D settings. Its compact size and flexibility make it an ideal choice for small-scale operations.

The DecFill ® product series is part of Dec’s Filling Solution Technologies easily integrable into end-to-end solutions from the raw material income to the final product.

1 Boyle’s law, also called Mariotte’s law, a relation concerning the compression and expansion of a gas at constant temperature. This empirical relation, formulated by the physicist Robert Boyle in 1662, states that the pressure (p) of a given quantity of gas varies inversely with its volume (v) at constant temperature; i.e., in equation form, pv = k, a constant. The relationship was also discovered by the French physicist Edme Mariotte (1676).

Source: Britannica