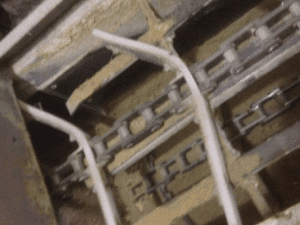

The conveyors, some as long as 240 feet, run with steel- bushed chain, welded steel backer flights and UHMW paddles. Tramp material would sometimes get into the conveyor, obstructing the movement of the chain and damaging paddles. Broken paddles carried downstream would damage other pieces of equipment. The chain was difficult to dismantle for paddle repair and the reshaping of steel backer flights inside the conveyor required a hot work permit, which meant extended downtime and production loss.

Solution

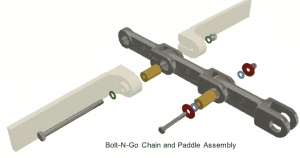

Replaced the steel-bushed chain and welded flights with 4B Bolt-N-Go chain and bolt-on paddles. Bolt-N-Go chain employs nylon paddles directly bolted on to the chain links so no welded steel backer flight is required. The paddles were manufactured using colored nylon to make them detectable by the plant’s color sorter. The chain’s unique bolted construction allows the paddles to be quickly and easily replaced while the chain is in tension.

Results

- Hot work permits no longer required for chain repairs

- Eliminated the risk of broken steel backer flights

- Reduction in downtime

- Reduction in planned maintenance

- More energy efficient

- Improved manual handling

- Health and safety compliance