With 15% – 85 % filling of the mixer volume providing multiple batch sizes and increased flexibility in only one machine. The size, number and positioning, geometric shape, and peripheral speed of the mixing elements are precisely coordinated to efficiently produce a whirling cross action three-dimensional product movement. The complete Mixing chamber becomes an Active Zone, whereby the entire product is constantly involved in the mixing process eliminating “dead zones” or low-movement zones inside the Mixer guaranteeing fast, precise predictable homogenous mixing. The mixing tools are specially designed to lift the material from the inside wall of the container without smashing the particles against the chamber wall which reduces the risk of product degradation resulting in the ideal Mixer for all products and applications and perfect for Mixes that contain multiple materials of varying bulk densities.

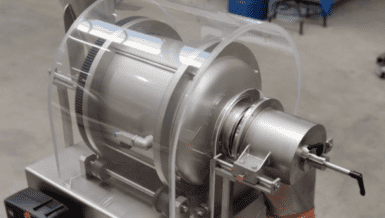

EXTRACTASHAFT

MIXSYS also offers the popular MIXSYS EXTRACTASHHAFT – QUICK CLEAN SYSTEM The MIXSYS EXTRACTASHAFT MIXER delivers well balanced and uniform particle distribution of blending ingredients. The EXTRACTASHAFT offers quick, direct access to clean the inside of the mixer chamber and the mixer shaft for quick changeover and verifiable results for complete product and operator protection. Mixers are available in capacities ranging from lab scale to in excess of 300 cu. ft.