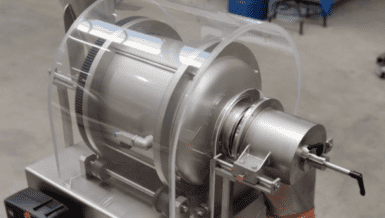

Pegasus® mixer with integrated pneumatic product feed

The impressive size, the smart accessibility options and the usual perfect finish is not unique to our customised Pegasus® mixers. What sets this mixer apart is the smart integration of pneumatic transport and mixing technology. This solution was chosen because it makes it possible to feed product with minimal damage and it results in a relatively very low mounting height. This solves two problems for the customer.

Final Inspection

Before a machine leaves our factory, we subject it to a strict inspection. We apply strict quality requirements and therefore check the machine on all possible points. If possible, we do this while the customer is present, so that they too can be sure that a perfect machine is being transported.

Installation on site

After the machine is approved, it is carefully packed and transported to the customer. Here our specialists are ready to install the large mixer with millimetre accuracy. This is a task for trained specialists who ensure not only a good but also a safe installation.