Using rotary drum mixers, like the SOFRAGIR, allows to blend any type of tea (black, white, green) with dried fruits or liquid aromas, without degrading the leaves, the texture nor the taste.

What is the advantage of using rotary drum mixers for tea blending?

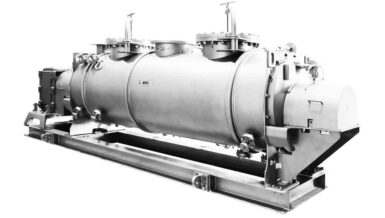

A gravity mixing process for tea blenders

The mixing action is achieved through the grooves welded to the tank that scoop out the leaves and dried fruit, which, combined with the effect of gravity, creates a cross flow in the mixer. The product is therefore not subjected to any other force, no tools are used to shear or damage the product as could be the case with paddles or a ribbon (see photos).

Sample 1: green tea blending in a MHR ribbon mixer for 1 minute (product degradation, leaf size reduction).

Sample 2: green tea blending in a SOFRAGIR rotary drum mixer for 1 minute (leaves intact).

No heating is caused on the particles and the tea leaves remain intact and natural.

Rotary drum mixer also have other important advantages:

- Low energy consumption compared to other technologies,

- Efficient mixing in very short cycle times,

- Efficient discharge and easy cleaning.

Aromatization and liquid spraying

Some tea manufacturers flavor their products to stand out from the competition. The rotating tank mixer ensures a very good distribution of liquids. The spray bar is located in the middle of the tank, so the spraying is done in the heart of the batch, during the rotation to guarantee a homogeneous and complete spraying.

No quality loss

Ribbon mixers or paddle mixers lead to a reduction in the granulometry of the leaves by up to 50%. A rotary drum mixer, such as the SOFRAGIR, guarantees a great quality mix, both visually and in terms of taste, which is means satisfaction for the final consumer.

Our SOFRAGIR rotary drum mixers mixers are adapted for:

- Mixing of tea, cocoa powder, milk powder, yeast extract and other fragile products

- Homogenization of powders

- Impregnation (flavouring or colouring of food products, regeneration of acid catalysts)

- Granulation of powders or fibers (fiberglass, polymers)

- Mixing of abrasive metallic powders