Palletizing bags has become more efficient and cost-effective with the introduction of advanced palletizing technologies. PAYPER, a leading provider of packaging lines, offers several palletizing solutions to meet the needs of different industries. This article will provide an overview of PAYPER’s 3 palletizer series, PPAL, GPAL, and RPAL and how they can improve production plant operations.

PAYPER designs and manufactures next-generation packaging lines for bulk solids: turn-key projects including dosing, weighing, bagging, palletizing and overwrapping. With a commitment to technological innovation and customer satisfaction, PAYPER has become a trusted partner for businesses seeking reliable, high-performance equipment:

Palletizing can be automated in two ways: conventionally or robotically. Learn more about the different palletizing technologies:

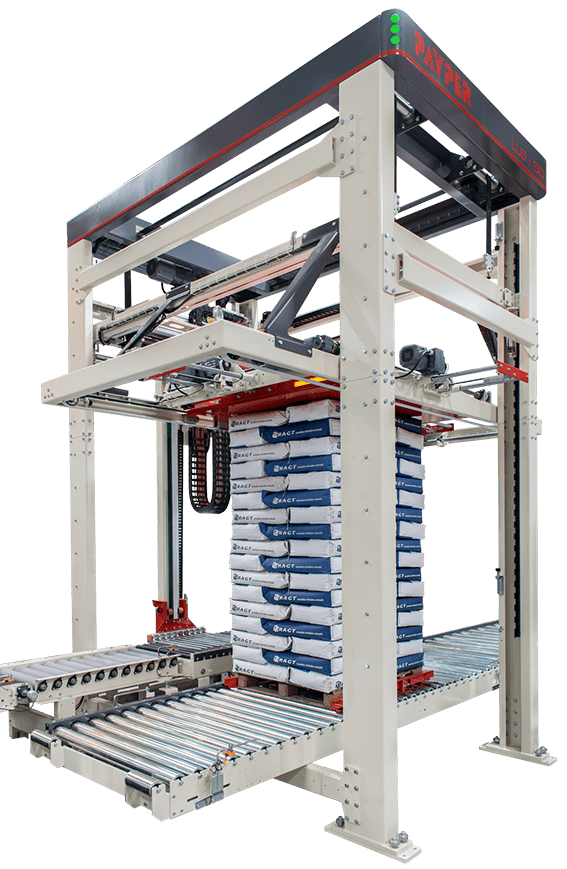

- The PPAL palletizers are speedy, heavy-duty and stable. This push-type palletizer is very fast, allowing high production capacities and creating fully square pallets with high stability. First, the front and side pusher system form the layers at right angles; then, each layer is compressed against the previous layer for extra stability. Push palletizers are highly flexible, allowing adaptation to different layer patterns, and are particularly suitable for valve bags and FFS bags. The highest output model in the PPAL series can palletize 2,800 bags/hour.

- The palletizers within the GPAL series are accurate and versatile. The GPAL clamp palletizer handles any type of bag. It is particularly indicated to work with open-mouth bags as it is designed to provide the perfect overlapping of the bags. The final result is a very stable and perfectly stacked pallet.

- PAYPER’s RPAL palletizers are equipped with advanced robotic technology and are the most compact of all palletizing solutions. They take up very little space and therefore they are ideal for production areas with a limited footprint. They are the most versatile palletizer, as they can handle any type and size of bags including open-mouth bags, also when overlapping is required. Depending on the bag and the desired layer pattern and production, different types of grippers are available to optimize any palletizing task. They are ideal for low to medium production capacity.

By utilizing advanced palletizing technologies, bag palletizing has become more versatile, cost-effective and productive. With the range of PPAL, GPAL and RPAL palletizers, PAYPER can adapt to the specific requirements of each business, offering high-speed, precise and efficient palletizing.

If you are interested in learning more about PAYPER’s palletizing solutions or have any questions about their products and services, please visit their website. You can also watch their informative videos on their YouTube channel to better understand their palletizing solutions.