In operation, positive product discharge is reliably achieved by means of regulated vibration uniformly applied to the body of the Model 821 Unloader, and in turn to the bulk bag. The vibratory action is produced by an adjustable heavy-duty motorized vibrator, powered by a TENV (AC) motor. When energized, powerful flow-inducing vibratory forces transfer from the body of the unloader into the bag (and the material contained within), effectively and efficiently discharging its contents. The outlet of the unloader flexibly connects to an independently supported Iris Valve that is mounted directly onto the inlet of Acrison’s Bag Spout Untie Receptacle. In its closed position, the Iris Valve maintains the bag spout sealed so it can be untied in a totally dust-tight manner. The Iris Valve is opened when ready to discharge product. The outlet of the Untie Receptacle typically connects to auxiliary process equipment for a totally dust-tight assembly.

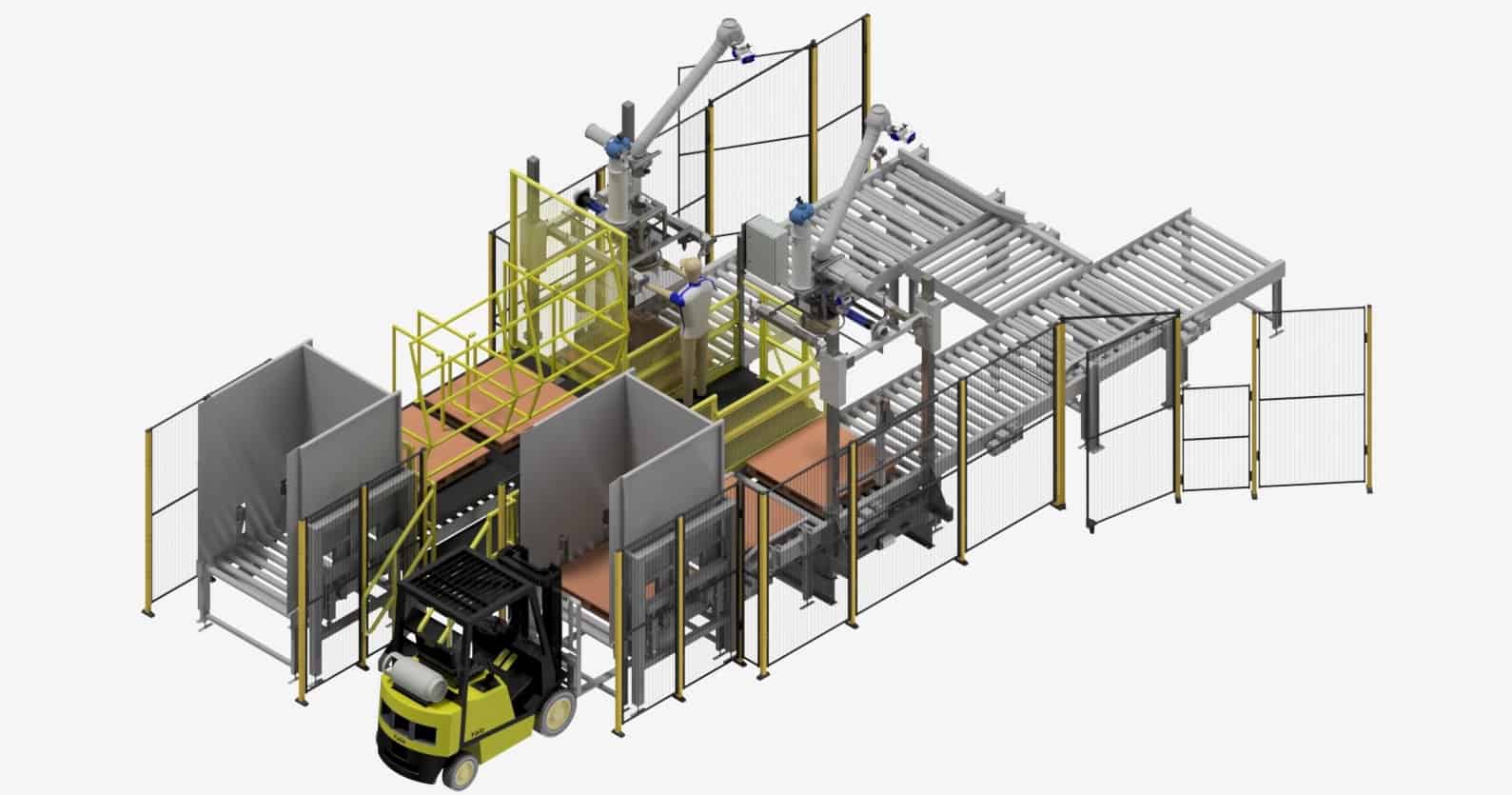

The Model 821 Unloader is optionally available with a pneumatically operated hoist and trolley and with several different Bag Lifting Racks, the selection of which is determined by the specifics of a given application and/or user preference. Bag Lifting Racks include either a lifting lug for attachment to a hoist or channels for the blades of a fork truck. Bag lifting racks may be equipped with Acrison’s Automatic Bag Tensioner and Bag Liner Tensioner. When furnished with the optional Automatic Bag Tensioner, lifting hooks with spring-actuated safety latches are provided for safe and positive attachment to the four bag lifting straps (or loops).