What is the return on investment? This question marks the beginning of every entrepreneurial idea. Which performance does a new facility achieve, at what cost and which additional benefits does it yield? This is the starting point for the company Daxner; to develop innovative solutions for the food industry; which are perfectly tailored to meet our customers’ requirements.

A well-renowned food producer invested more than 30 Million in the new production facility in southern Germany where all kinds of dry mixed products like soups, sauces, bouillon, seasonings, desserts

Given

Innovative process technology

The system design ranges over 3 levels and covers the whole production process on an area of 4,000m²: from the storage of raw materials in outdoor silos, the transport to the day silos, their filling, dosing, weighing and the mixing process with 6 separate blending lines through to the discharge in IBCs (Intermediate Bulk Containers).

Daxner developed an innovative system with integrated easy clean equipment design, dust-free powder handling

The facility with its state-of-the-art quality and hygiene concept was put into operation in 2017 in accordance with the international food standards (IFS) and guarantees utmost process safety.

Efficient raw material handling

All ingredients are divided

More than 1,000 small components (e. g. spices) are stored in an automated storage and retrieval system in approximately 9,000 crates. Here, all recipes with less than 1 kg are managed and dosed manually. The components are delivered automatically from the storage by the order management system and transported to the 4 manual dosing stations. The individual components are weighed into a transport unit (trough with barcode identification).

Maximum flexibility and cleanliness with container transport system DCS

A total of 50 IBCs are used with a volume of 1,200 ltr each. The Automated Guided Vehicle system (

Due to the pre-weighing of the components at the weighing stations, the IBCs can be filled at a high rate of up to 12 containers/h. After collecting the automatically dosed components, the IBCs are positioned below One of Four manual dosing stations. Here all small components are dumped as complete bags and/or as a part /subset from the automated storage and retrieval system. After adding the manual components, the IBCs are picked up by the AGV system and then conveyed to the level above the mixing line with a lifting device. Subsequently, they are positioned at the Daxner container discharge station with an electric forklift. The discharge station is equipped with a self-centering frame and a connection socket. A discharge aid with a dockable vibrating motor enables the container to be residue-free after discharging.

Four powerful

Detailed technical solutions

Every production plant by Daxner is tailored to the individual requests of the customer. The outstanding engineering work paired with the companies-own production, creates detailed technical solutions which are turned into comprehensive plant concepts during the design process.

– Container discharge system: An automated device for opening and closing the container valve is built onto the container discharge system. The container is emptied using a manual valve with a hand operated lever which has been automated and opens and closes fully automatically with two pneumatic cylinders. In emergency situations and for cleaning purposes the container can also be closed manually with the hand lever.

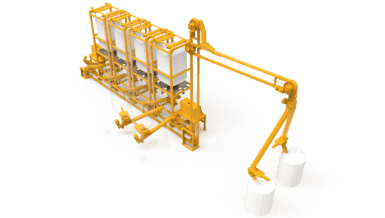

– Mobile Big bag discharge station: The day bins are filled by a state-of-the-art, mobile Big bag discharge station. The loading platform is located one level above the installed day bins and is connected to them with an embedded filling nozzle. The mobile Vig bag discharge stations are placed above the filling nozzle and connected with a lever mechanism, creating a closed off and dust-free system.

– Docking system for various Big bag sizes: When the mixing process is completed, the components are fed into Big bags. Industry standard docking systems usually fit or are suited to one particular Big bag size. To adapt it to different sizes then requires a further level of manual intervention. Daxner developed a mechanism which enables the system operator to adjust the docking station to various Big bag sizes with minimal effort. To keep the Big bag handling as simple as possible, a new suspension for a continuous adjustment of the bag size was implemented.

Plant control system

The plant control system provides an optimal interaction between process and controls engineering. ESAweight is connected to the overriding ERP system and controls, monitors and documents all production processes. It coordinates the container transport and guarantees the smooth operation of the automatically dosed components. The main advantages of this system lie in the comfortable operation, as well as the complete traceability and parallel order processing.

“You accompany a project from the first ideas to the final commissioning. In the end you are fascinated by how perfect the different facilities and components operate together”, concludes Hartwig Scheidlberger, head of sales at Daxner, about the successful megaproject.