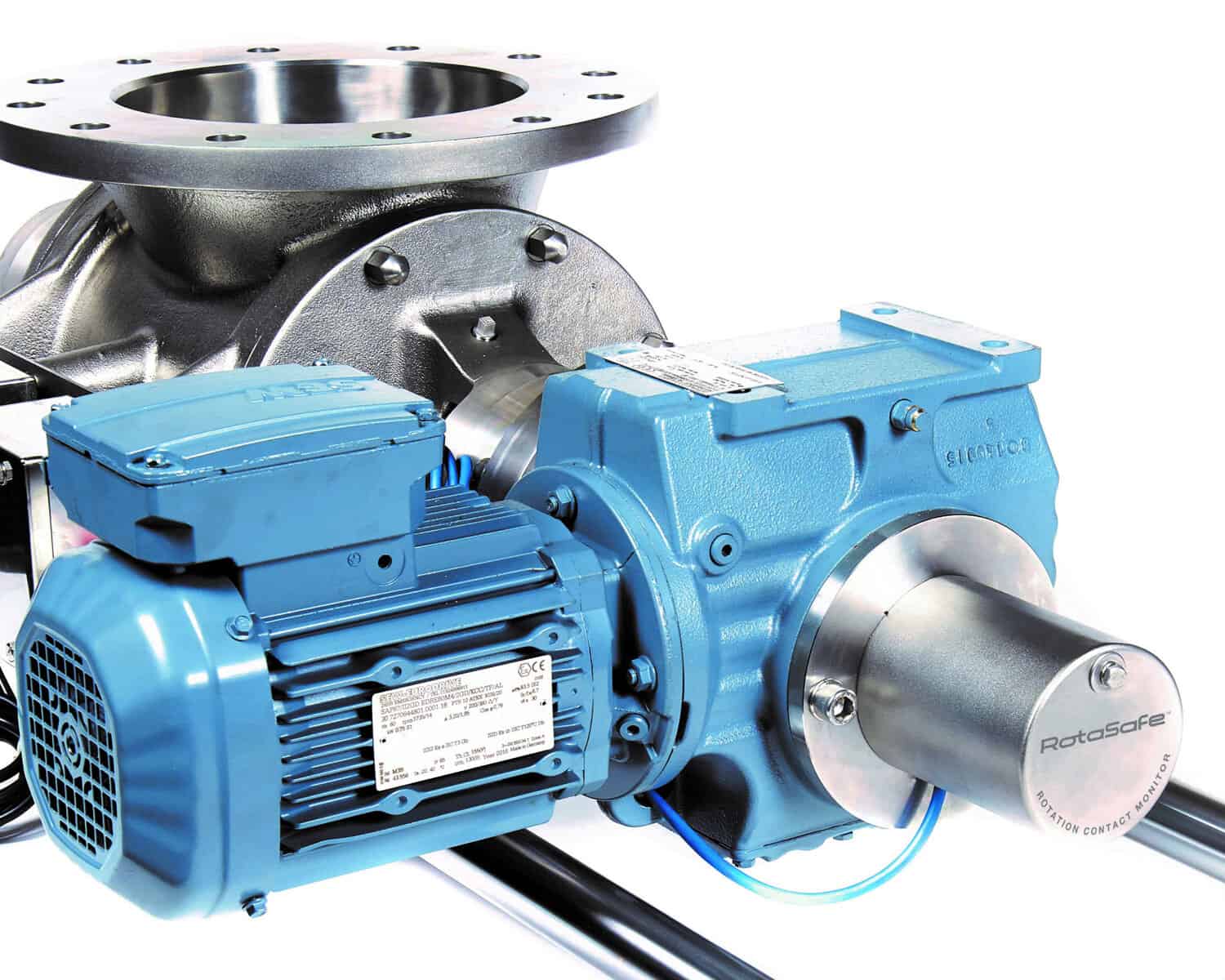

The filling and closing line use an innovative bag holder that protects the operator when attaching the bag to the filling spout. The dust extraction system helps to provide a clean and safe environment. The scale is a net weigher with gravity feed. The bag closing system is either by sewing or welding.

The bag can be closed by simple sewing, fold (of the upper flap of the bag) and stitching; or by heat sealing in the case of plastic packaging (PE, PET). The plant can process flat and gusseted bags in paper, raffia, plastic, from 10 to 50 kg, with a fully automatic format change.

Applications: granular products, including corrosive ones

The plant, in the completely stainless-steel version, is designed for weighing and packaging aggressive granular products such as salt and fertilizers, ensuring reliability, safety, and long life.

For the packaging of products such as rice, grains, feed, pet food, vegetable, forest charcoal, and minerals, Concetti offers the mild steel version with the parts in contact with the product in stainless steel

Concetti’s semi-automatic packaging systems significantly improve bagging operations, combining high productivity, flexibility, and safety for operators.