Coffee is the most popular morning drink and must be prepared quickly and easily to get a good start to the day. That’s why coffee pod machines have conquered households in a short amount of time.

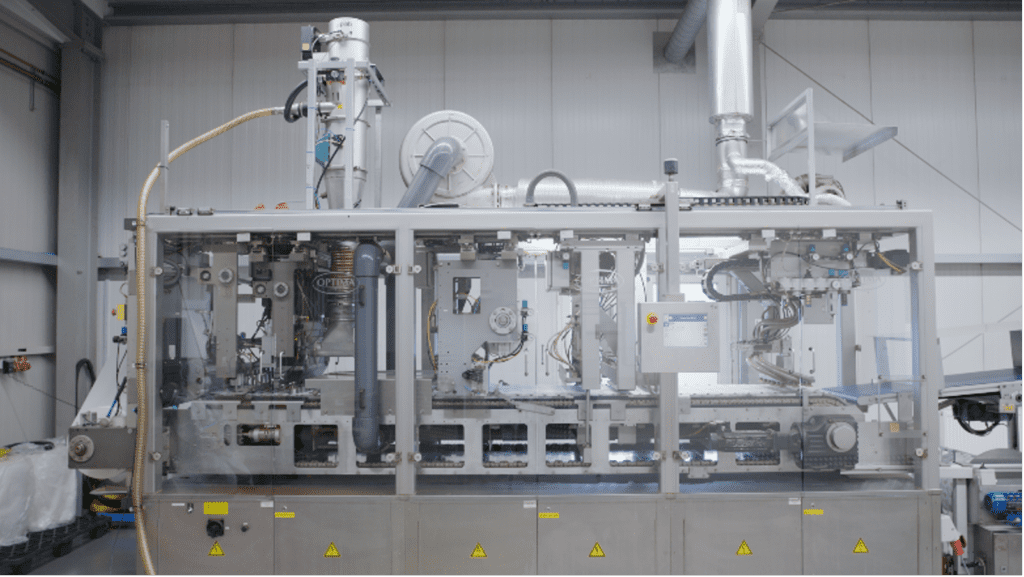

Coffee pod production should be just as uncomplicated as preparing your morning coffee with the pods. That is why Minges Coffee Roastery relies on Piab piFLOW®f conveyors for filling their pods with coffee powder, as well as other Piab products for their capsule production and packaging machines.

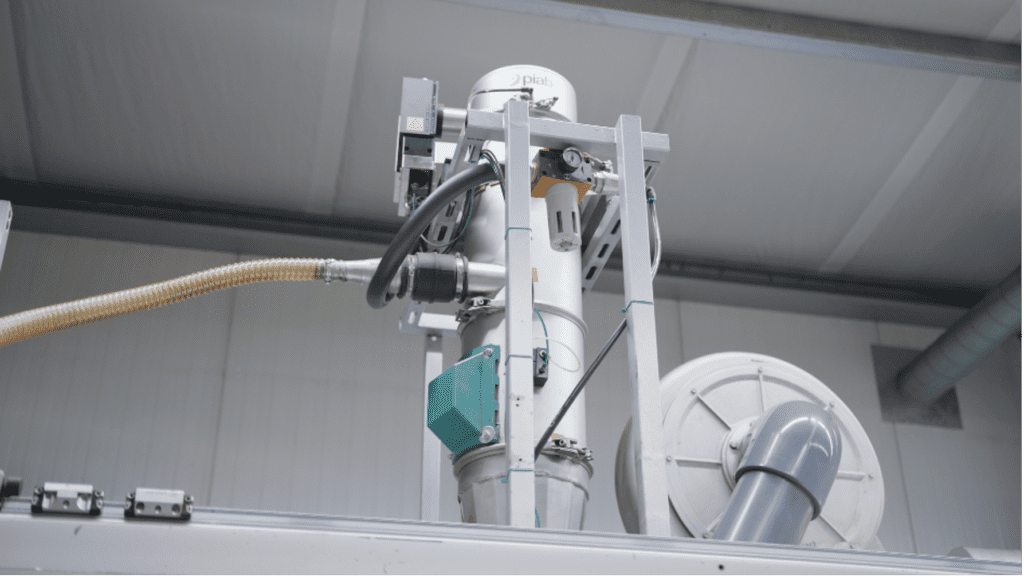

In the first stage of the coffee pod production process, the coffee powder is emptied into a collecting container from a big bag. From here, it is transferred into the vacuum conveyor body through a flexible hose and discharged into a hopper equipped with a sensor. When the sensor indicates that the hopper is filled with the correct quantity, the powder is released into the packing machine where the individual pods are filled. A rail system carries the finished pods to the packaging line, where the packing boxes are erected with Piab suction cups.

Andreas Fritz, head of technology and maintenance at Minges Coffee Roastery explains: “We wanted a conveyor to fill the pod production system that effectively does its job, so we don’t need to worry about this part of the process. We were particularly pleased by the simple and robust design of the Piab piFLOW®f.”

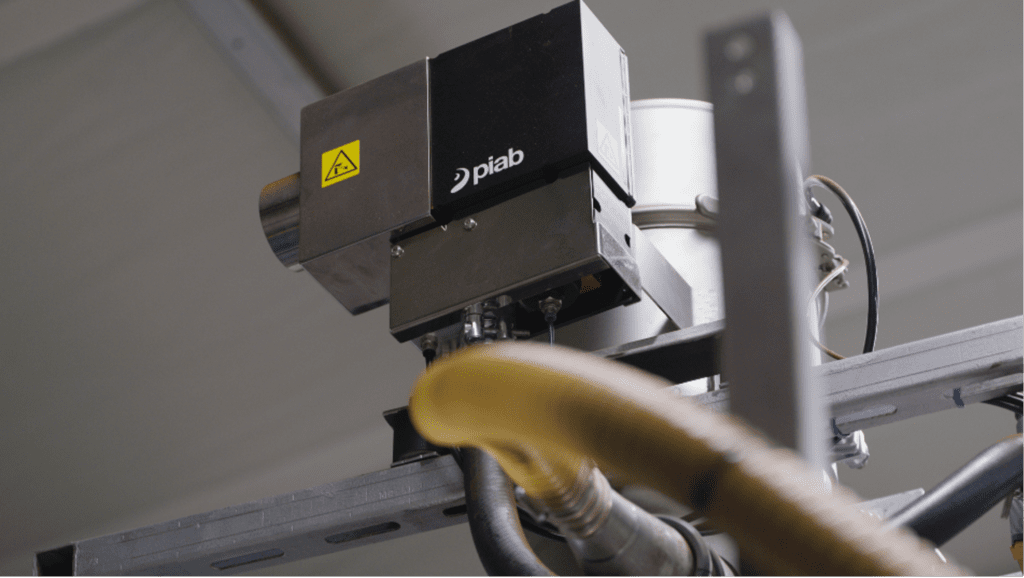

“We replaced a simpler vacuum conveyor using a gravity flap. Previously, the flap didn’t open and close as it should have, and the filters of the conveyor were constantly clogged,” he continues. “The Piab vacuum conveyor has no moving parts and requires minimal maintenance. The filters are of higher quality and clean themselves after each cycle with a filter shock, so we have easily solved the problems we had with the old technology with the piFLOW®f. We also reduced dusting in the production space due to the new closed setup. It allows us to achieve better occupational safety while avoiding product contamination.”

“When changing products, the piFLOW®f is very easy to clean. The entire conveyor – including all parts, like filters and seals – can be disassembled, cleaned, and reassembled for the next production run without needing any tools, it is extremely fast. It takes just a few simple steps due to a quick-lock (clamp) system.” adds Francisco Diaz Arriola, responsible area sales manager at Piab.

“Replacing the old solution with a Piab vacuum conveyor has also helped us improve product quality. Previously the freshly roasted coffee beans were brought to the machine in big tanks and fed manually into the conveyor and small grinder, which led to aroma losses. Today we do the grinding earlier in the process and we feed the cooled coffee with the Piab vacuum conveyor to fill our 7-gram coffee pods. Then, they are picked up from the belt with Piab suction cups and placed into the packaging unit,” says Andreas Fritz, explaining the decision to use Piab vacuum conveyors at Minges.

The piFLOW®f vacuum conveyors are operated with Piab’s patented COAX® multistage ejectors in the vacuum pump. The vacuum is generated by ejecting compressed air from a nozzle system. It enables both high system efficiency and a high absolute vacuum level, practically eliminating blockages in the conveying line.

“Apart from the technical excellence, exceptional cooperation with Piab hallmarked with short support response times and commitment to promises were also essential for us. Spare parts are reliably available. A dedicated contact person is always there for us with fast and flexible support times, helping us to reduce downtime,” Andreas Fritz concludes his explanation of the reasons for working with Piab.

The Piab piFLOW®f is widely used in food industries, often as an alternative to mechanical conveyors when dust-free conveying or low maintenance is necessary/wanted. Another advantage is that the COAX® technology is the most energy-efficient way to generate a vacuum. Piab conveyors for the food industry are equipped with stainless steel (ASTM 304) bodies. All parts, including the conveyor body and sealings, which are in direct contact with the conveyed product, meet FDA and EU 1935/2004 standards to comply with the requirements of the food industry. Piab conveyors are certified according to ATEX dust. All conveyors are available with either an ejector driven vacuum pump or a mechanical pump. The standard piFLOW®f has a capacity of 4 tons per hour, and the large one manages up to 7.5 tons per hour.