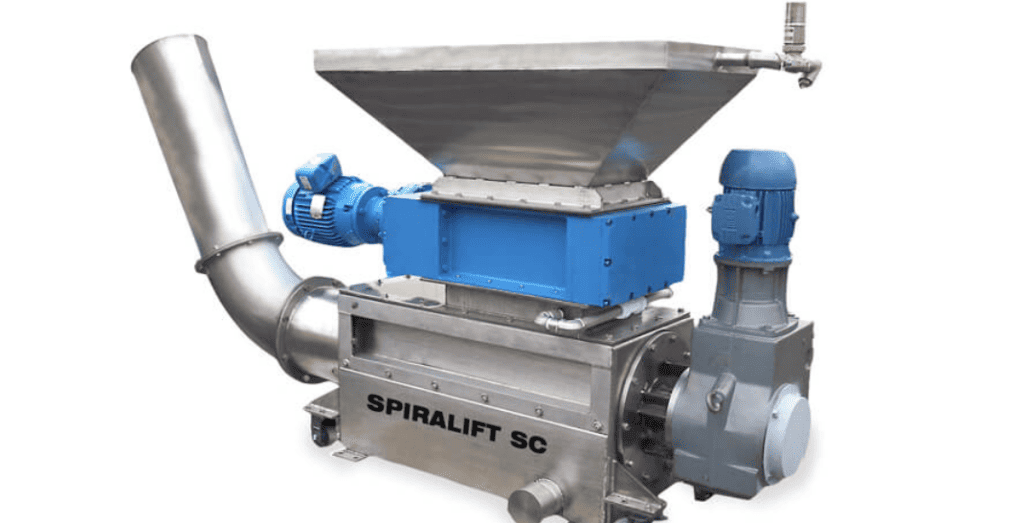

The processed solids are discharged as ground, uniform particles in a compacted plug, ideally conditioned for disposal. The SPIRALIFT SC washer compactor utilizes a rugged TASKMASTER® Screenings Grinder to reduce solids to a small size exposing multiple surfaces. The ground solids are intensively washed to remove contaminants and organics. The screenings are then compacted and conveyed by unit’s powerful screw press and organics are returned to the flow.

Operation

As screenings drop into the SC hopper, they are washed by the upper spray nozzles and then ground by the TASKMASTER® shredder. Next, the SPIRALIFT SC intensively washes organics and flushes them back into the system. The screenings are then compacted in the unit’s press zone. Finally, the processed screenings pass through a discharge pipe and are deposited into a bin, bag or conveyor — washed, ground and reduced in weight. The grinder and press technology, along with highly rugged construction, makes the SC uniquely effective.

Configuration

The SPIRALIFT SC is provided complete with hopper, shredder, tank enclosure, solenoid valves, spray manifolds and controller. The PLC-based controller monitors and integrates the entire system. The SPIRALIFT SC is provided in several models: The SC1620 features a 10HP TASKMASTER shredder and a 3HP shaft-mounted auger drive. It handles up to 175 ft3/hr of solids. The SC8520 features a 5HP grinder, 3HP auger drive for up to 50 ft3/hr of solids. Other sizes can be provided as well.