Processing, trading, distribution

Ravago processes industrial rubber and plastic waste into granules, pellets and chips to be used as raw material for new products. In addition, this Belgian company manages the worldwide trade and distribution of chemicals and sales of so-called building solutions products, such as construction films, pipes and guttering.

New recycling technologies

Ravago’s ambition is to reuse as much plastic waste as possible, and this aim is shared by Finland’s Neste, a world leader in the production of renewable diesel and in renewable solutions for the aerospace and plastics industries. In 2019, the companies joined forces. Together, they aim to process more than 250 kilotonnes of mixed plastic waste per year. This strategic partnership combines Ravago’s expertise in the mechanical recycling of plastic waste, Alterra Energy’s liquefaction technology (liquefying of plastics) and Neste’s expertise in hydrocarbon processing.

The reliability of mechanical recycling

Chemical recycling is interesting because it is innovative and taps into new, demanding sectors. Nevertheless, mechanical recycling remains important for Ravago. Mike Janssen, Project Manager at Ravago: “It’s a very reliable method that fully meets the requirements of our current clients. That’s why we are continuously investing in these systems. We invest in new lines for factories worldwide where quality is paramount in order to achieve a long life cycle, a high degree of user-friendliness and safe working conditions for operators. And we invest in modifying and replacing obsolete or non-energy-efficient installations.”

Joint innovation

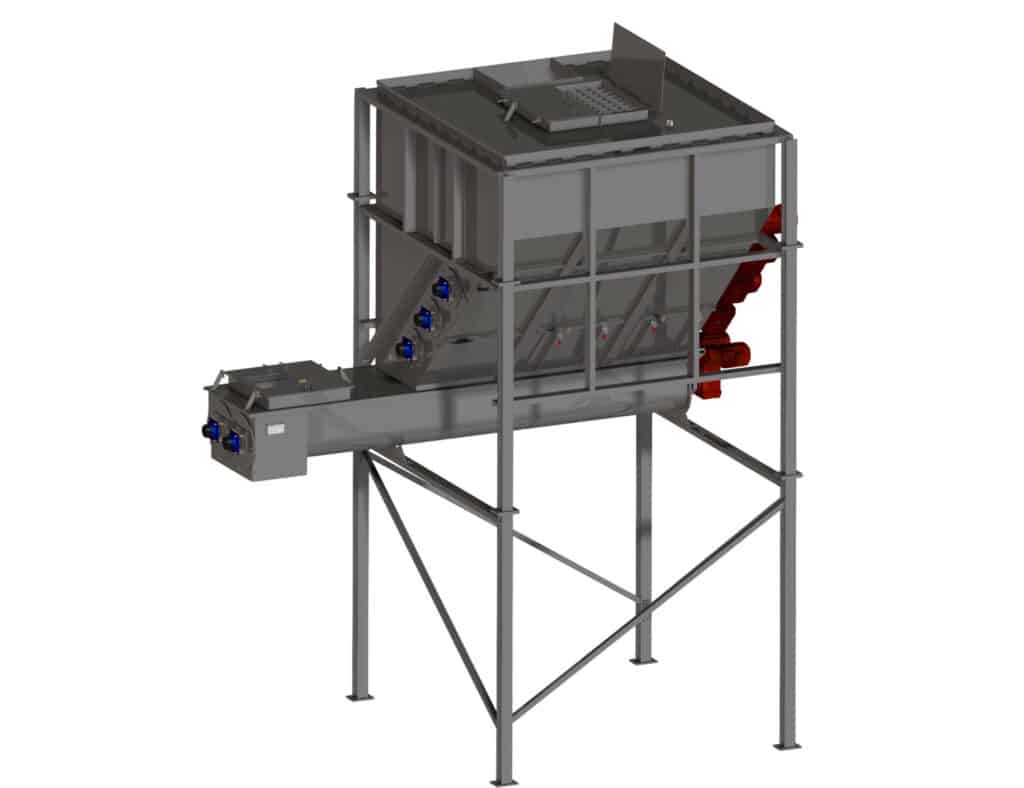

Van Beek has been developing and supplying buffer silos for decades. For example, sales manager Joram van der Heijden and project leader Johan van Drongelen developed a buffer silo for Ravago specifically for the collection of various plastic films. “What is the product, what are its properties and what are the customer’s expectations? We used these questions as our starting point. In addition, we collaborated in finding the best way to incorporate our machines into the installation”, Joram explains.

Van Beek made some minor adjustments to make the installation even more reliable and user friendly for its operator. Joram: “Often, customers will encounter the need for minor adjustments at a later stage. Usually it’s no problem carrying out these adjustments. The big advantage of having a good relationship between customer and supplier is that you can continue to develop the products.”

Waste film in many shapes and qualities

Van Beek’s plastic film buffer silos and collection screws can now be found in almost all of Ravago’s plants. Mike calls them ‘amazingly beautiful products’. “The shape and composition of our waste films varies enormously. Transport systems are generally unable to cope with this. Over time they will develop cracks, for example. Van Beek’s products show almost no wear and tear, are easy to maintain and are safe. The systems also have an excellent robust finish in stainless or galvanised steel. Completely customised, which is exactly what we need in our factories.”

An excellent collaboration

“Van Beek is known for the high-quality standards they set for their final product. This is why we contacted them 10 years ago”, Mike tells us. “We are very pragmatic; we send them a drawing and ask whether they can accommodate us. That’s usually not a problem for Van Beek. They are familiar with our standards and our way of working. Their service is excellent, from the moment there is a question or a requirement, up until after delivery and installation. If there is anything that goes wrong, it’s addressed quickly and never allowed to become a problem. In Van Beek we have definitely found a reliable long-term supplier”, concludes Mike.