The refined white sugar in your favorite recipe, the coarsely grained light-brown raw sugar on the barista bar … they all possess different characteristics that ultimately determine their respective grades.

Polarization, degree of refinement, and color are just some of the key factors that go into establishing these different types and grades of sugar.

Yet as the industry seeks more efficient ways to get their product from farm to table, increased attention is being paid to moisture control – and, by extension, the optimization of drying and cooling stages in refining plants that exist prior to packaging and distribution.

During sugar processing, the cooling and drying of crystalized sugar are considered the most important step after the purification process to guarantee a high quality of the finished product. Sugar drying removes excess moisture from the sugar using heat while cooling the sugar brings it to an ideal temperature for storage and transport.

Without processing sugar in this way, clumping occurs during storage, thereby degrading the quality and value of the final product.

The evolution of cooling

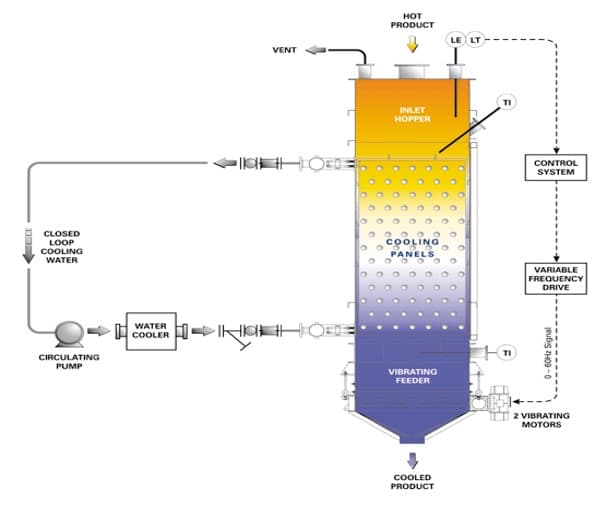

Over the past 20 years, Solex Thermal Science has provided a proven best-in-class cooling solution for the sugar industry that combines bulk solid mass flow with indirect heat transfer.

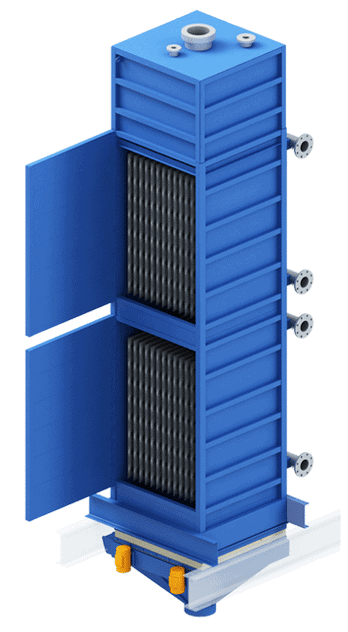

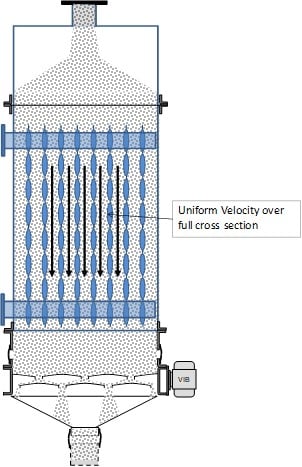

The patented heat exchanger technology utilizes vertically oriented plates with internal channels to provide a large heat transfer area within a compact unit (figure 1). The sugar crystals flow by gravity between the plates, while a cooling fluid (e.g., water) flows counter-current to the sugar crystals through the plate’s internal channels. This eliminates any contact between the sugar and the cooling fluid, providing a high-quality product while providing efficient and uniform cooling.

A mass-flow discharge device guarantees the uniform flow of sugar through the cooler, thereby producing uniform temperature distribution (figure 2).

This compares to the fluid bed and rotary drum equipment that has traditionally been used for cooling sugar. Though well-proven, both pieces of equipment use air in direct contact with the sugar as the cooling medium. Not only does this introduce a greater potential to contaminate the sugar (e.g., bacteria and odors) compared to indirect cooling, but both also require sophisticated air handling and cleaning systems, infrastructure and operating energy.

To guarantee the performance of Solex’s sugar cooling technology, a proprietary modeling software called ThermaPro® is used to accurately predict how long the sugar crystals need to stay in the cooler to reach the desired cooling temperature. It does this by performing detailed calculations based on material thermal properties and process requirements including the sugar’s bulk density, specific heat, thermal conductivity, input temperature, and flow rate.

This is followed by in-house equipment fabrication where attention to detail is paid. Solex prides itself on providing robust equipment with low operating costs.

The benefits

Solex’s indirect heat transfer technology, through its simplicity of operation, eliminates dust emissions, the need for exhaust fans, filters, dust collectors, and other peripheral equipment required for air treatment when air is used in a process. This greatly simplifies cooling operations and supports operators’ objectives for minimizing their impact on the environment.

It also cools the sugar using only 0.4 kWh per tonne, compared to fluid bed and rotary drum coolers where the energy requirement is typically around 5.0 kWh per tonne. This is a 90 percent reduction in the energy required for cooling. In addition to substantial cost savings, this also supports a reduction in the GHG footprint of sugar production when fossil fuels are used to produce energy.

And because of its modular design, Solex coolers can easily be retrofitted into existing sugar processing facilities as it has a small installation footprint. In some cases, it can be used in conjunction with existing equipment to allow for an increase in production capacity.

For example, the exchanger can operate as a secondary cooler after an existing fluid bed or drum cooler when cooling capacity becomes a constraint. Another option is to convert a combined drum dryer and cooler into a single drum dryer, then add a Solex cooling unit to provide the needed cooling capacity. This retrofit allows for increased sugar production capacity, as well as a higher quality of finished sugar.