While flow control valves are used to allow or prevent bulk material discharge from different locations, diverter valves are used to reroute powders, pellets and granular bulk materials from one source to multiple destinations (or reverse) as part of a dilute or dense phase pneumatic conveying system.

Butterfly Valves

Butterfly valves consist of a disc which rotates 90 degrees in circular hollow body. When fully open, it turns and becomes parallel to the flow direction, allowing minimum flow resistance. When fully closed, it is perpendicular to the flow direction and sealed against a seat.

Slide Gate Valves

In slide gate valves, a rectangular blade made of thick sheet metal moves horizontally in the valve body. When the blade is in fully open position, bulk material in powdered or granular form falls freely through the valve. It can also be kept open at intended level to control product flow speed.

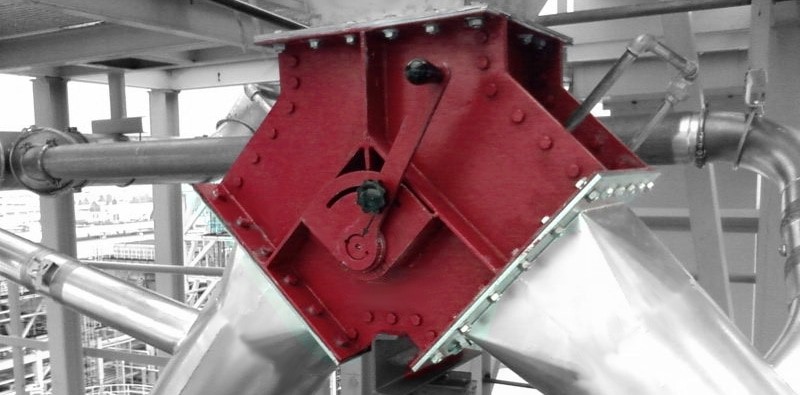

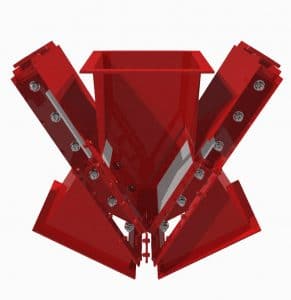

Flap Type and Flexible Tube Diverter Valves

Flap type gravity discharge diverter valves are designed to divert the gravity flow of bulk solids from one feeding point to two or more receiving points. A wear-resistant swivel flap is used for diverting the flow inside the valve. Depending on the application it consists of flexible polyurethane rubber inner surfaces for better sealing.

The small angular deviation between the inlet and outlet ports and minimum change in cross-section area through the flap type pneumatic conveying diverter valves provide smooth material flow and reduce pressure drop in the conveying line.

Flexible tube diverter valves are suitable for pressure and vacuum conveying lines. Since there is no change in the cross-sectional area through the valve, the pressure drop is kept minimum.

Multiport Diverter Valves

A distributor pipe rotates around an axis to connect a single port to multiple ports with maximum sealing. The pressure drop is kept minimum.

Flow Control Gate Valves

Flow control gate valves provide controlled discharging of bulk solids like cement and fly ash from silos and bins. They have upper and lower chambers divided by a fabric that maintains a constant airflow to the upper side. The upper chamber has a rotating drum with an aperture around its perimeter. Rotating the drum in one direction provides dust-tight shut-off. Rotating the drum in the opposite direction provides an adjustable cross-sectional passage for material flow. By adjusting the exact position of the drum, bulk material flow speed can be adjusted with precision.

Custom Designed Valves

In addition to the standard product range, custom-designed valves are available for the most demanding and special applications. Different bore sizes, unique flange connections, non-standard body designs, and special accessories are accomplished through our engineered products group.

For abrasive materials and food applications, the valve parts are constructed from 304 or 316 stainless steel which ensures maximum durability and safety. Pipe connections can be supplied as either plain pipe ends or flanged as required. Custom engineered production incorporates problem definition, conceptualization, design, validation, production, and installation.

Atex Certified Diverter Valves

Potentially explosive atmospheres occur where fine dust of combustible bulk materials like coal, sugar, wood, and starch are handled. These risks may occur when the combustible dust suspends on-air, accumulated on hot surfaces, slides through chutes or conveyed within pipes, etc.

Any kind of ignition source like a spark, overheating, excessive friction might lead to hazardous dust explosions in the zone. To decrease dust explosion risk to acceptable levels, industrial processes should be designed and operated carefully. Polimak produces ATEX certified diverter and flow control valves for such processes.