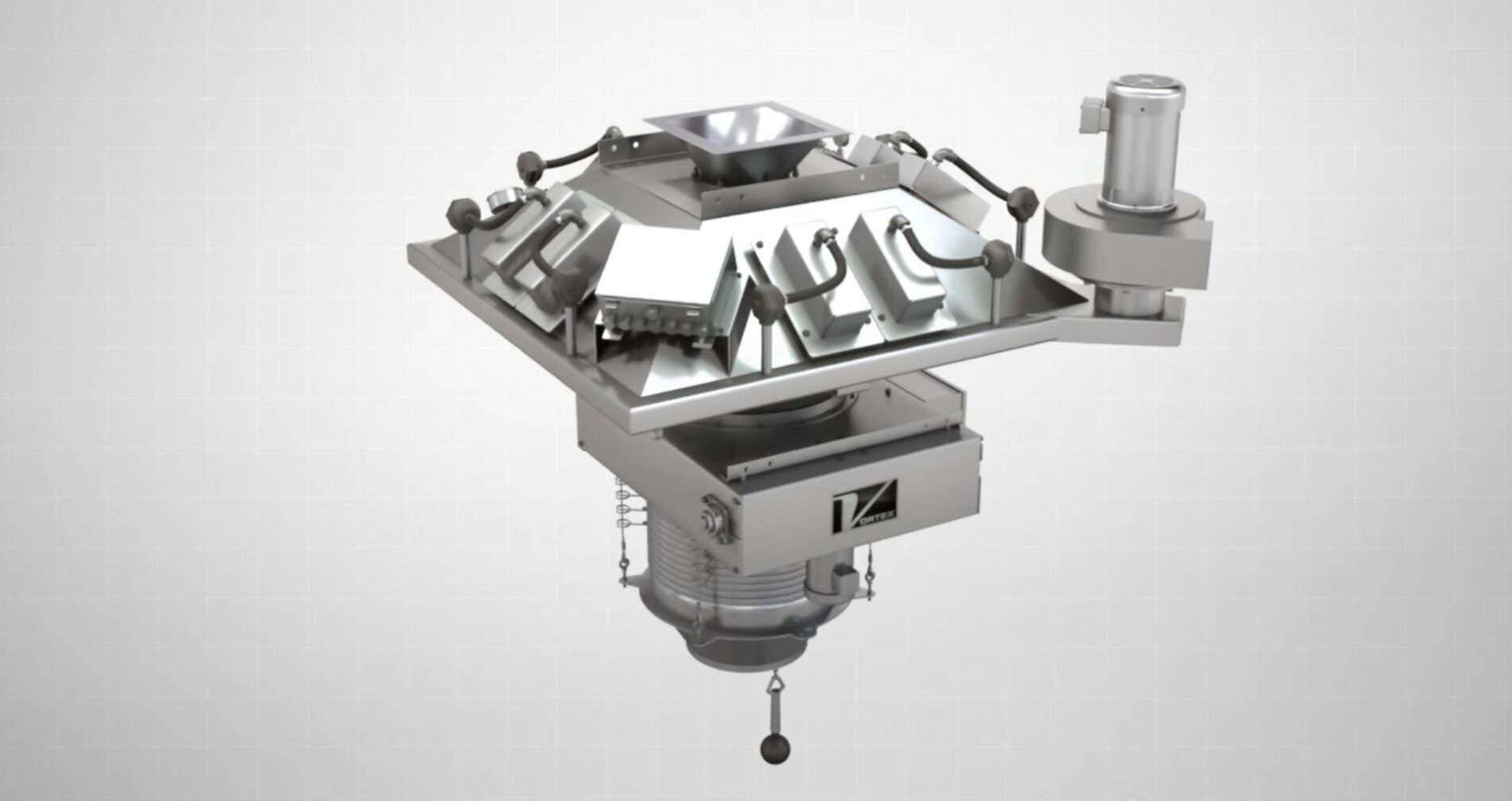

Silo blockage

Powder has a natural ability to move and fall when it is stored in a silo or a hopper. A key variable that will have an impact on the flow is its cohesive strength. It is therefore imperative to know your powder properties in order to design the desired silo.

In a silo, hopper or bin, the powder is exposed to various pressure levels, because the top powder consolidates the powder below it. These pressures are however rather different compared to liquids. Powders in a conical section of the silo act somewhat similar to a Roman brick archway, in which the arch carries the mass above. Due to this pressure, some solids tend to be more compacted and become cohesive. When powders are or become more cohesive, the arch becomes stronger and the lower the resulting pressure acting on the powder nearest to the outlet. This is a major hindrance for facile discharging of powders.

Arching a.k.a. bridging

Arching occurs when an adequate amount of cohesive powder is stored in a hopper or silo which doesn’t have a steep enough cone wall or a large enough outlet relative to the pressure acting on the powder. In order for powders to have an optimized flow, the material needs to have a constant pressure that is high enough to keep the powder flow going. This pressure is dependent on the outlet shape and diameter as well as on how easy the powder can use the sides of the outlet as a support to consolidate itself and create arches.

Ratholes a.k.a. piping

Another phenomenon that can occur is the formation of Ratholes. When this happens it is usually because the flow is primarily taking place along the centerline, in other words the powder will only flow through a channel at the center of the hopper whereas the rest of the material is compressed up against the sides of the silo, creating non-flowing zones referred to as ‘dead zones’ or “stagnant zones”. These compressed powder zones often move either in an avalanche cascading manner with material chunks possibly clogging the silo outlet or the material is not discharged at all which is very critical for products with a limited shelf life.

Segregation

Segregation could be viewed as the opposite of mixing, segregation stimulates the separation of solids. Segregation can occur at any stage of industrial process and has various causes. During filling of the hopper, typically a heap is formed and by continued dosing particles start to roll from such heap. Larger particles tend to roll further than fine particles or powders. This causes a higher density of smaller particles in the center of the silo compared to the higher density of larger particles towards the outer wall of the silo.

During an industrial process with poor flowing products, often excessive vibrations are applied to make the product flow. During this process of undergoing these vibrations the larger and smaller particles can even more separate from each other and divide into bands of various density throughout the silo. Some of these bands can become more solidified than others, leading to possible blockage covering the outlet or resulting in irregular flow during the unloading process.

Because of the occurrence of segregation the product displays a non-uniform mixture that can cause detrimental dosage issues, think of food, feed and pharma powder handling for example. Segregation becomes more pronounced when the silo displays funnel flow type discharging.

Designing a silo

During the design of a silo the objective is to find the correct cone hopper half angle and the correct diameter of outlet that will keep the correct amount of pressure on the powder, high enough to break the possibly formed arches and thus creating a natural and smooth product flow, i.e. mass flow following the first-in first-out principle.

Key silo design parameters

- Discharge diameter (avoids arching and ratholing)

- The discharge angle = hopper half angle

- The silo wall material

- The volume of the silo

- The discharge rate from the silo

- Environmental conditions such as temperature and relative humidity.

- Process conditions like cooling down of a product in the silo

In part two of this article we will expand further on calculating the key design parameters of a silo as well as look into other powder (non)flow and storage phenomena. We will also share some of our own results on the impact of humidity and temperature on powder flow and the transport of moisture in consolidated materials.