The mixture of ingredients is intended for the manufacturing of flooring tiles in different colors and textures. In order to ensure a perfect regularity tile appearance, it is necessary to make highly accurate dosing of each ingredient.

Thus, the mixture is produced with an accuracy of ± 10 g, and after, the finished product feeds a bagging machine for packaging in 30 kg bags.

SCAIME Solution

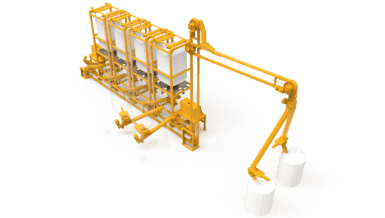

PPI has designed a fully automated system for big bag storage, dosing, and mixing of ingredients. The system uses SCAIME weighing components integrated into the Schneider Electric Ecostruxure automation architecture.

SCAIME products:

Automation Products:

- 1 PLC Schneider Electric M340

- 1 HMI Schneider Electric Magelis

Architecture

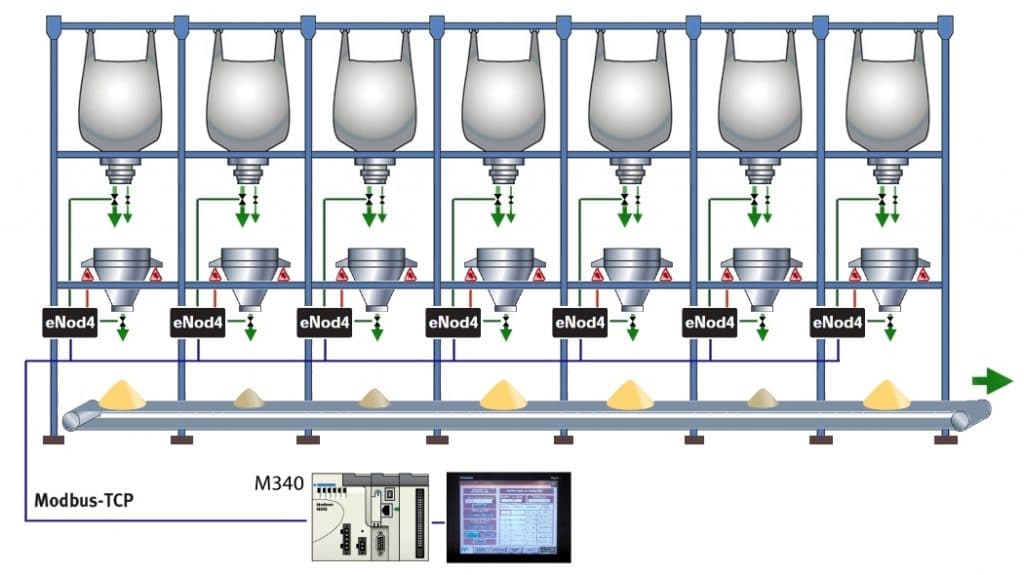

The dosing system consists of 7 hoppers weighed by F60X load cells mounted on RUBBERKIT damper kits.

In this architecture, the M340 PLC handles the overall system control and management formulas, while the dosing tasks are assigned to the controllers SCAIME eNod4-D. Each eNod4 manages the filling of weighed hoppers. At the end of dosing, the M340 controls the transfer of ingredients to the bagging machine.

eNod4-D dosing controllers connected to the M340 PLC by Ethernet MODBUS-TCP network

The connectivity between the eNod4 controllers and the M340 controller has been validated as part of the technological partnership between SCAIME and Schneider Electric for weighing applications. SCAIME validated solutions are available on Exchange.se.com.

Customer Benefits

- Optimized architecture with devices dedicated to tasks for which they are ideally suited.

- With the dosing process controlled by eNod4-D, the system achieves high speed and high accuracy dosing.

- Easy integration into EcoStruxure thanks to eNod4 Ethernet MODBUS-TCP networking capabilities.