It is impossible to imagine a sensible, individual diet without muesli. Its composition and preparation make it quite individual. One of the most traditional organic food producers – Bauckhof Mill – reveals the challenges of combining the different ingredients and how the ideal mixture is produced.

What constitutes a healthy, trend-conscious diet? It contains vitamins and minerals, fiber, proteins, little fat, and sugar, but enough valuable carbohydrates. In addition, in our hectic and demanding everyday lives, food should always be close at hand, have a long shelf life, be quick to prepare, and still be healthy, or even better, performance-enhancing

Muesli fulfills these requirements in next to no time. It is always available, has a long shelf life, and is quickly ready to eat. Its ingredients make it a symbol of a healthy, even primal diet. It satisfies your appetite for ages and provides many valuable nutrients. And let’s not forget that muesli tastes good because it has the right mix of sweet, salty, soft, and crunchy. However, this mix varies greatly from person to person – just like tastes. But due to the variety of raw materials available, hardly any food is as suitable for “mass customization” as a personal muesli mix. It can even be ordered online in single quantities. Sales of muesli in the retail sector amounted to a whopping 439 million euros last year.

You are what you eat

Today, consumers not only place increasing importance on the composition of their food. Its origin must also be acceptable. Sustainability, climate protection through regionality, and high-quality ingredients are part of the trend towards a discerning and healthy diet. If you consider the list of ingredients of many muesli mixes on supermarket shelves, it will be apparent that a surprisingly large number of these products contain amounts of industrially processed sugars such as dextrose, glucose, sucrose, maltodextrin, and invert sugar syrup. The fat contained in the crunchy muesli in the form of palm oil does not belong there either, as it often originates from huge palm plantations that displace the cleared primeval forest as a monoculture.

It is therefore only logical that the amount of organic muesli will increase as consumers become increasingly aware of environmental and quality issues. The ingredients of healthy muesli are not only “organic” but in the best case are regional and “organic”.

This is precisely what the Bauckhof Mill stands for. Unlike almost any other food brand, Bauck represents the values of organic, sustainable food production. The predecessor of today’s Bauck GmbH was founded back in 1969 as a marketing company for biodynamic foodstuffs. Many of its products even bear the Demeter seal, one whose criteria go far beyond many organic seals. But to maintain their standards, organic associations lay down strict rules for cultivation and processing. And the EU organic seal and the hexagonal German organic seal provide evidence that the grain was allowed to grow pesticide-free and reaches the muesli with the same degree of purity.

Bauck muesli therefore not only satisfies the stomach but also gives us a clear conscience. The consumer is happy to pay a little more for this but expects the muesli mix to be of a clearly noticeable and tasty quality, which makes it stand out from other readymixes as being beneficial.

Taste decides

The selection of local grains – especially oats – and other top-grade ingredients from the region, plus 100% organic ingredients not available in the region, is a prerequisite for high-quality muesli mixes to make them a preferred breakfast component.

The second prerequisite is the ideal mixture – in both senses of the word. An in-house product development department at Bauckhof Mill is responsible for the highest-quality raw materials and the outstanding taste of their many muesli varieties. New mixtures are constantly being created.

That’s why it’s important that precisely this mixture is found on the spoon in the right proportions to create a pleasurable experience for the consumer. This is only possible when all components of the product have been mixed to perfection. So, on a tour of the Bauck production halls, you come across mixers from amixon®.

Mixing heterogeneous components quickly and gently

Natural products of organic quality often have a base of oat, spelt or millet flakes. These should be mixed as gently as possible with other components such as sultanas, nuts, chocolate chips, dried and freeze-dried fruit.

The mixes, therefore, range from a basic muesli mix with just a few ingredients to versions with several dozen ingredients for more complex mueslis. The ideal muesli mixture is therefore very demanding in terms of process technology because the shape and structure, especially of the raw materials used, should not change during the main mixing step in the process.

It is common for the mixing time to be just 10 to 30 seconds for muesli and cereal mixes. This extremely short and therefore very gentle mixing process means that the particle structure of sensitive components in the muesli, for example, is preserved in the best possible way and the consumer receives a top-quality product.

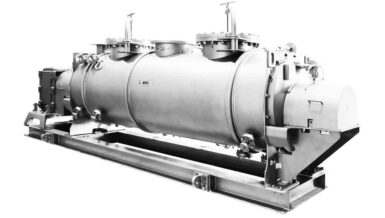

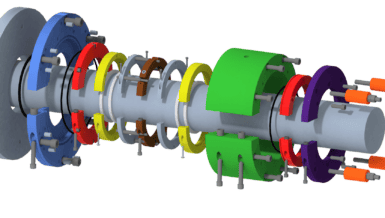

amixon® precision mixers, mainly the vertical twin-shaft mixer (HM), are used to achieve this result. The underlying operating principle of two co-rotating helical blade mixers causes the upwards helical flow of the mixed materials on the periphery and a downwards flow in the center using gravity. This three-dimensional flow achieves a technically ideal mixing quality that cannot be further improved in practice

The mixing process is reproducible in amixon® equipment with zero-clearance. Even the filling quantities in the mixing chamber can vary from 15 to 100% of the actual nominal volume with no loss of mixing quality.

Sensitive tasks in production: emptying and cleaning

However, attention must be paid not only to the extremely short and very precise mixing process but also to emptying. Here, too, it is important to empty the chamber as gently as possible, without segregation and, ideally, without leaving residues.

While the SinConvex® mixing tool, patented by amixon and designed as a Multi-Plane® tool, continues to rotate slowly, one or more large outlets in the base plate open for emptying. This creates an optimal outflow of the product and meets the above criteria.

Ergonomic, manual dry cleaning can then be carried out through the large, hygienic inspection doors in the mixer. The doors are produced using the CleverCut® method. The O-ring in the groove seals very close to the product and practically free of dead space. The design is permanently gastight, dust-proof and waterproof. The inspection doors are opened by manually actuating the KwickKlamp® closures. Electromechanical safety interlocks only allow the inspection doors to be opened when the system is disconnected from the power supply. Wet cleaning is also possible and can even be fully automatic.

amixon® mixers comply with the specifications of the EHEDG and the FDA, and therefore meet the highest requirements for the hygienic preparation of high-quality, fragile and powdery goods, especially cereal and muesli mixtures, tea mixtures, spices, dietary foods and flavors. The equipment also meets all the requirements of GMP standards.

Thanks to these and numerous other features of amixon® precision mixers, muesli producers are able to achieve a balance between recipes created for private consumers and large batches for the B2B sector.

Checklist for mixing muesli at Bauck

- Does the mixer achieve ideal mixing qualities and very short mixing times?

- Is an especially product-friendly mixing process ensured?

- Can filling levels vary from 15% to 100% but achieve the same mixing quality?

- Can efficient emptying of residues of at least 99.98% be achieved?

- Are the highest hygiene standards maintained?

- Does the equipment have large inspection doors that close without creating dead space and that are permanently gas- and dust-tight?

- Can the chambers be cleaned wet or dry?

History of Muesli

It was the Swiss doctor and nutritional reformer Dr. Maximilian Oskar Bircher-Benner who, around 1900, as director of his “Lebendige Kraft” (living force) sanatorium on the Zürichberg, treated his guests to an apple diet. Today he is considered the inventor of muesli. At that time, the raw food meal called “d Spys” in Swiss German consisted of softened oat flakes mixed with grated apples, nuts, lemon juice and sweetened condensed milk. It was promoted under the name “Birchermues” as an easily digestible evening meal.

In the 1940s, it was thanks to another pioneer of wholefood nutrition, Professor Werner Georg Kollath, that this cereal meal was further developed and found its way onto home breakfast tables as a ready-made product in the 1950s to 1970s. The triumph of muesli began in health food stores. Today, these ready-made, grain and seed mixtures fill entire supermarket shelves.