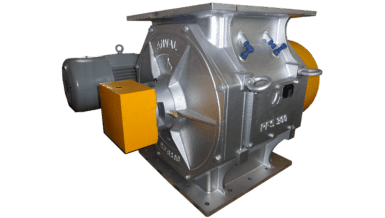

This analogy represents HAVER & BOECKER ́s “symphony of technologies”: depalletizer, bag applicator and packer are perfectly matched, digitally interconnected and centrally controlled to ensure a consistent and steadily high-performing packing process.

The entire high-performance packing system is controlled fully automatically by the bags to be filled. By scanning the QR code of an empty bag, the line receives the information on which product type will be filled into this bag design. All components of the line and the product supply adjust fully automatically to this information and this type.

The process: After scanning, the new AMICUS® depalletizer picks up the specified bag stacks from the pallet and places them on the holding table at the RADIMAT®. The bag scanner in the RADIMAT® reads the QR code for checking and for data transfer to the QUAT2RO® System Monitoring. Next the bags are automatically shot onto the spouts of the ROTO-PACKER® fully automatically, then filled and conveyed.

Different types of bags can be used, which are provided with a QR code. The code contains the information with which product the bags are filled, giving the entire process even more security. The ROTO-PACKER® can be equipped as SEAL Edition for sealing the bag valves after filling.