Among its star products, Vibrating Feeders for any kind of solids but mainly for dry materials. Also, other vibrating machinery for bulk is accompanied by these feeders in their portfolio; vibrating screens, conveyors, sieves, spiral elevators, vibrating tables…

Not only Research and Development, but also all knowledge and experience shared from their Licensee, Syntron Material Handling Equipment, become a great support for their engineering team, and also for the application specialists in charge of proposing the best vibrating handling solution for every particular material handling challenge.

Tarnos vibrating feeders for dry materials have many applications in different industries, products, and processes.

In order to cover all the odds, Tarnos designs the equipment with different technologies, for what they manufacture and supply electromagnetic vibrating feeders, and electromechanical vibrating feeders.

Tarnos vibrating feeders are sub-resonant tuned, two-mass, spring-connected systems. These features enable feeders to work consistently under material damping and other varying head-load conditions with negligible changes in trough stroke. Sub-resonant tuning maintains stroke consistency and speed stability, thus delivering higher capacities at controlled feed rates. Precise, sub-resonant tuning is a key characteristic of both types of Tarnos vibrating feeders.

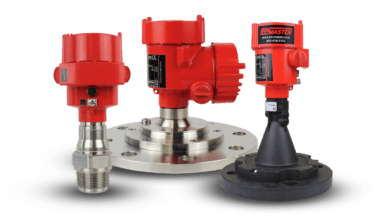

Heavy-duty electromechanical or electromagnetic vibrating feeders are ideal for uniform and controlled feeding of a wide variety of bulk materials from storage piles, hoppers, bins, and silos to perform in the mining, aggregates, glass, cement, chemical, food, wood, recycling, and steel industries. They will be designed with both technologies, mechanical o magnetic, depending on the needs of the jobs to execute.

High capacity electromagnetic feeders are especially suitable when instant start-stop is needed with no passing through resonance and also very accurate regulation of flow through a potentiometer or analogical signal.

They work with very small amplitude and high frequency, taking care of product to handle. There is no maintenance as there are no parts to lubricate, and they are totally stable and smooth.

These are robust and reliable equipment thought for hard jobs and to accomplish other demands of their main industries such as proven certifications for Hazard areas when a project requires so; ATEX executions.

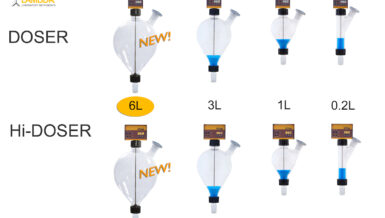

Light electromagnetic feeders are most commonly used for the food and packaging industry, also automation, offering unmatched flexibility and reliability, making them ideally suited for a number of applications and materials. They are typically used in feeding, dosing, mixing, blending, sieving, batching, grinding, packaging, flaking, sprinkling, aligning, freezing, and drying applications.

Again these feeders can perform controlled, accurate and stable dosing taking care of the product that handle, with 0 maintenance.

These small capacities electromagnetic feeders have been adapted for the demands of these light industries, for which they are executed with as much possible stainless steel components, FDA paintings, and quite high IP levels.

Standard vibrating electromagnetic drives are also supplied to many Original Equipment Manufacturers that include these units into their own designs; multi-head weighers, optical selectors, counting machines, lines of biscuits, etc.