Recyclable fractions from waste should not only be separated according to type, but also recorded precisely in terms of quantity. Belt conveyors are usually used to transport waste. The use of a built-in belt scale for weighing of recovered recyclable fractions during the transport on the belts is an obvious solution – but is often rejected as a solution, particularly in the area of slag conditioning and separation, due to the low feed rates.

The MAV Group operates plants at several locations in Germany for the processing of waste incineration grate ashes, which also contain valuable metals, among other things. These recyclable fractions are separated in several process stages and thus returned to the metal processing industry as recycled metal.

For precise balancing, the plant in Krefeld was now also to record the quantities of the individual types of recyclable fractions or metals. With this task, they turned to MTS MessTechnik Sauerland GmbH.

During the inspection of the plant, it became clear that no classic built-in belt scale could be used for this planned application due to the low feed rates and the plant situation. Nevertheless, the quantity of the recyclable fractions was to be recorded exactly during the running production process.

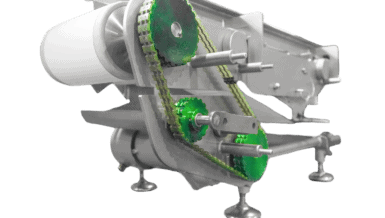

For this purpose, MTS MessTechnik Sauerland developed a conveyor discharge weigher for installation at the discharge point of the belt conveyor.

The conveyor discharge weigher CDW consists of a weighing hopper with a pneumatically downward opening flap and a robust support frame. The support frame is permanently installed on the discharge of the conveyor unit; the weighing hopper is suspended from three load cells.

The sorted recyclable fractions are fed to the conveyor discharge weigher via belt conveyor and fall into the closed weighing hopper at the discharge point – until a defined setpoint is reached. Then the belt is stopped and the weighing hopper is statically weighed. The flap opens and the hopper is emptied. The flap closes again, the hopper is tared and the feed starts again for the next weighing cycle. Up to 50 weighing cycles can be performed per hour.

The filling and emptying process, as well as the load cell signals, are controlled and evaluated by the powerful control unit ModWeigh Batch. On the one hand, the control unit records the weight value of the weighing hopper and accumulates the individual batch values in the totalizer; at the same time, the ModWeigh also generates the feed rates in kg/h or t/h from the weight values of the individual batches and the time unit determined for a weighing. The flap is controlled autonomously via the ModWeigh. An additional transmission of the measuring data to the customer PLC can take place via Profibus DP or Profinet.

The new conveyor discharge weigher CDW was installed and commissioned by MTS MessTechnik at MAV in Krefeld in July 2020. Since then, the scale has been working reliably and safely, delivering very accurate quantities of the secondary metal directly after the sorting process.

The conveyor discharge weigher CDW is made of painted steel as standard, optionally made of stainless steel. In this application, all heavily stressed components are made of Hardox. The flap is operated pneumatically via powerful cylinders with additional electronic position monitoring of the flap.

Conclusion

The new MTS weigher CDW, a conveyor discharge weigher is particularly suitable for recording low and medium feed rates from 200 up to 5,000 kg/h. The CDW achieves very precise accurate measuring results because of the weighing is performed statically. The scale can also be retrofitted into the existing customer system with little effort.

Further conveyor discharge weigher have already been ordered by the MAV Group due to their good function and measuring accuracy.