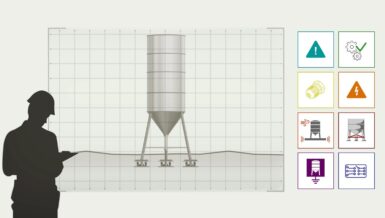

One measuring system is often used for this purpose: weighing the loading silos with daisy strain gauge sensors. These are small sensors, only 8 cm long. Their main advantage is that they are only screwed onto the steel supports of a loading silo. The sensors can thus be easily retrofitted, can be installed at any time without production interruption, even on partially filled silos, and does not interfere with the silo statics.

The functional principle of the daisy sensors is similar to that of a classic load cell: The sensor detects the material deformations (here in the steel support) that occur due to the silo being emptied during loading or due to the silo being filled. This results in a change in resistance in the sensors, which is recorded as a voltage signal by the control unit and normalized to a weight value.

For the use of the daisy sensors, the silos must comply two requirements: first, the existence of a self-contained silo structure with stable steel supports, and second, a total weight that achieves a measurable surface pressure.

One disturbance variable in daisy measurements is the heating of the supports. This is because heat also generates a change in the length structure of the steel supports, which is detected by the sensors. If all sensors are heated slowly and simultaneously by the ambient temperature, this error is negligible. In the case of one-sided heating, e.g. due to solar radiation only on the two front supports, measurement results with partly unsatisfactory deviations often result in the area of the sensors despite insulation of the supports.

In order to eliminate the disturbance variable ‘temperature’, the technicians of MTS MessTechnik Sauerland have now developed the following solution: additional sensors for temperature measurement are mounted on the steel supports, with whose measured values the results of the daisy sensors are corrected.

This solution also convinced the German company from the glass recycling sector, which processes around 170,000 tons of waste glass annually. Part of the glass flows become glass powder, which is first stored in silos and then transported by trucks to the further processed companies.

In a pilot project, MTS MessTechnik Sauerland GmbH installed daisy measurement for a loading silo. For this purpose, a daisy sensor and a temperature sensor were mounted on each support, whose signals are evaluated by the ModWeigh static comfort control unit. The electronics itself also takes over the correction of the temperature influence on the signals of the daisy sensors.

The ModWeigh static shows the current loading weight and other additional information on a separate LCD colour display and can be easily operated via modern menu navigation. In addition, a large LED display has been installed directly on the silo to enable truck drivers to better read the current loading weight.

During loading, an accuracy of less than +/- 200 kg is achieved with 25 t total loading and a loading time of less than 10 minutes.

These results also satisfied the German company, which decided to purchase the measuring system after a three-month test phase. Time-consuming unloading or reloading of trucks has since belonged to the past. Internal processes have thus been decisively improved.